34

82493 - ALTO

- This permits introduction, during water filling of the sprayer, of powders or liquid treatment products.

This equipment gives an excellent mixing of the product with the water and makes spraying operations

easier.

OPERATION

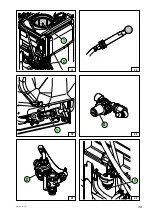

(figure 31)

- Connect the hopper's piping (6) to the valve (1) located on the sprayer.

- Dip the filling stick (4) into the tank of your sprayer.

- Hook the top of the filling stick under the edge of manhole.

- Fill the tank partly, (approx. 100 litres, see filling operation, pages 16 and 26).

- Lift the cover of the hopper.

- Fill the hopper with phytosanitary products.

- Adjust valves:

Manual control version:

▪ Put the valve (V1) in position (figure 25 page 31).

▪ Valve (V2) in position

(figure 29).

▪ Valve (1) in position

(figure 31).

Electric control version:

▪ Put the valve (V1) in position (figure 25 page 31).

▪ Valve (V2) in position

(figure 30).

▪ Valve (1) in position

(figure 31).

In both cases:

▪ Engage the tractor's power take-off and increase its speed to 540 rpm.

▪ To rapidly empty the hopper:

▪ Replace the cover,

▪ open the valve (5) in position (figure 31).

- The product is draw up into and incorporated in the sprayer's tank.

RINSING THE HOPPER

- Open the valve (2) in position (figure 31) which actuates the rinsing boom (1) (figure 32).

RINSING THE CANS

- Position the product can on part (2) (figure 32).

- Open the valve (3) in position (figure 31) to actuate the cleaning nozzle (3) (figure 32).

AFTER THESE OPERATIONS

- Adjust:

▪ Valve (1) in position

(figure 31).

- You can now finish the tank's filling.

- After the filling operation (figure 33):

▪ Remove filler hose (2),

▪ refit the plug (1).

INCORPORATION HOPPER - ALTO 300/400/600/800

Содержание ALTO 300

Страница 2: ...2 82493 ALTO...

Страница 4: ...4 82493 ALTO...

Страница 14: ...14 82493 ALTO...

Страница 17: ...17 82493 ALTO 5 6 4 3 V4 V1 1 1 2 3 4 2 3 V2...

Страница 19: ...19 82493 ALTO 7 8 1 1 2 3 4 V2 V2...

Страница 21: ...21 82493 ALTO 9 10 1 V1 V2...

Страница 22: ...22 82493 ALTO...

Страница 25: ...25 82493 ALTO 11 12 13 1 3 2 V 1 1 3 2 V2 4...

Страница 27: ...27 82493 ALTO 16 17 19 18 14 V4 V1 15 1 2 3 1 V2 V3 V2...

Страница 29: ...29 82493 ALTO ON OFF 20 21 24 23 D P Elec 2 4 1 1 1 V V 22 V2 V2 1 2 3...

Страница 31: ...31 82493 ALTO 27 D P Elec 1 ON OFF 28 2 4 1 1 V 26 25 V4 V1 1 2 V2 V V2 3...

Страница 32: ...32 82493 ALTO...

Страница 33: ...33 82493 ALTO OTHER SPRAYER FUNCTIONS...

Страница 35: ...35 82493 ALTO a b a a b b 31 30 32 1 2 3 4 5 6 2 3 29 1 33 1 2 V2 V V2...

Страница 37: ...37 82493 ALTO 35 36 34 V4 Alto 300 400 Alto 300 400 Alto 600 800 Alto 600 800 1 1 3 2 2 2 3 2...

Страница 39: ...39 82493 ALTO 37 41 40 38 39 1 42 1 S 1 2 E...

Страница 40: ...40 82493 ALTO...

Страница 41: ...41 82493 ALTO MAINTENANCE OF THE SPRAYER See Safety checks maintenance of the Sprayers manual No 82 471...

Страница 46: ...46 82493 ALTO...

Страница 47: ...47 82493 ALTO MAINTENANCE DIAGRAM SPRAYING CIRCUIT...

Страница 49: ...49 82493 ALTO 1 2 3 7 4 9 6 5 8 10 17 12 13 14 16 15 ON OFF 11...