26

TECHNICAL ASSISTANCE CENTRE

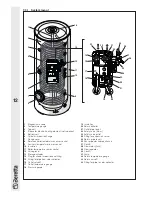

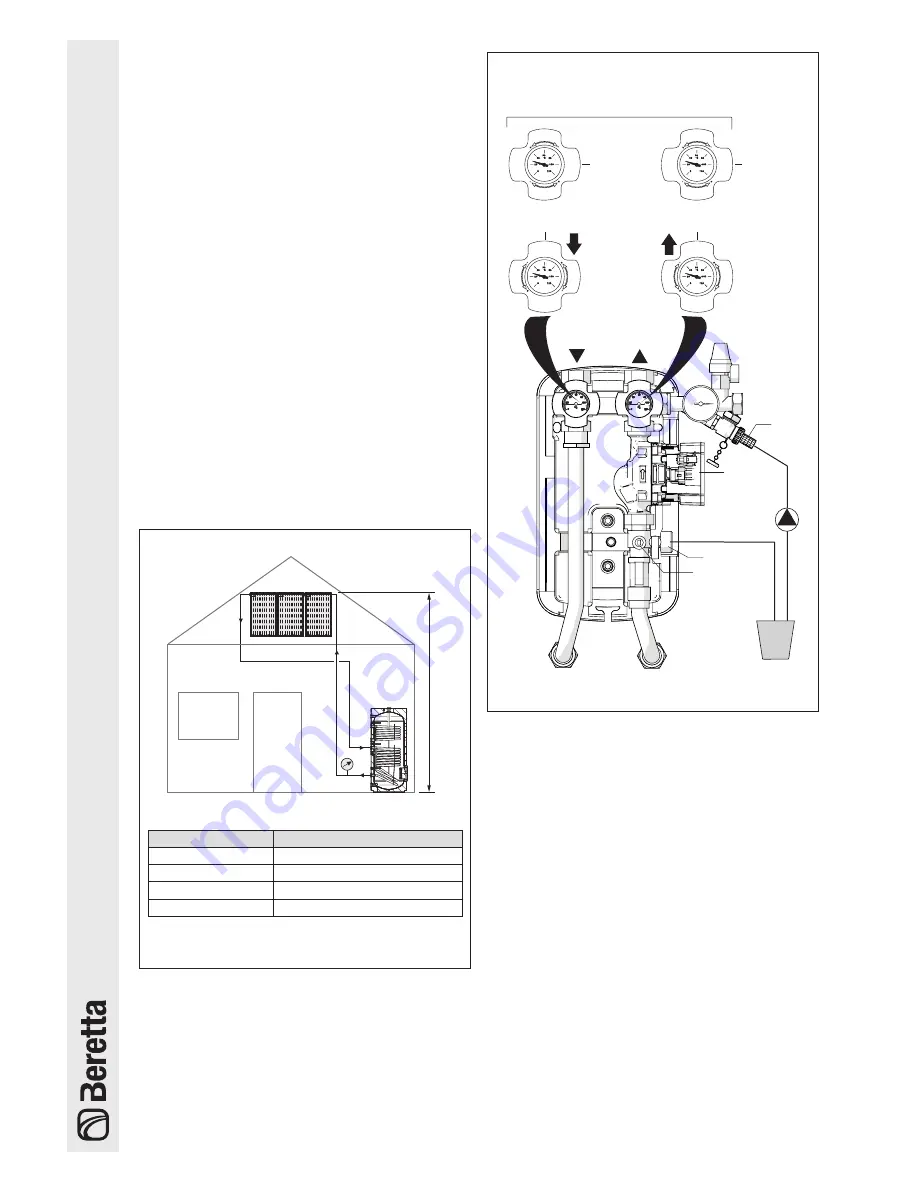

12 INITIAL STARTUP

FILLING THE SYSTEM

a

Do not fill the system in bright, sunny conditions or if

the collectors are hot.

1 Turn the knobs of the outlet and return valves (M) and

(R) fully anti-clockwise.

Close the flow regulator (V) (so that the screw slot is

horizontal).

2 Open the manual bleed valve and any vent valves at

the highest point in the system and keep them open

throughout the filling operation.

- Pump the heat transfer fluid around the circuit with an

external filling pump until all air bubbles have been

eliminated. Close the manual bleed valve and any

vent valves opened previously.

- Temporarily raise the pressure in the system to 4 bar.

- Start up the system for about 20 minutes.

- Bleed the circuit again from step 2 until all the air has

been removed.

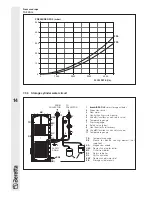

- Set the circuit pressure according to the table on the

next page in order to ensure a minimum pressure of

1.5 bar at the height of the collector field.

- Close the cocks (A) and (B) and re-open the flow

regulator (V).

b

Use a manual bleed valve, which should be installed

at the highest point in the system, to ensure that all air

bubbles have been eliminated from the circuit.

H

H

Pressure at boiler

up to 15 m

3 bar

15 - 20 m

3,5 bar

20 - 25 m

4 bar

25 - 30 m

4,5 bar

General rule: p [bar] = 1.5 + H [m] / 10

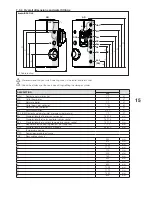

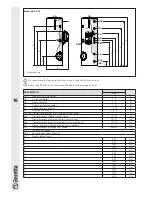

Upward

flow only

(non-return

valve function)

Position of the knob

of the valve R - M

90°

0°

90°

Flow stopped

0°

Anti-freeze mix

R

M

Pump

Heat

transfer

fluid filling

pump

A

B

V

Outlet

group

Return

group

Technical Assistance Centre