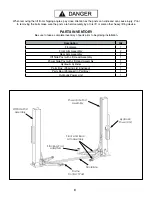

15

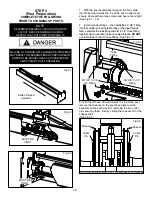

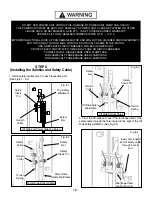

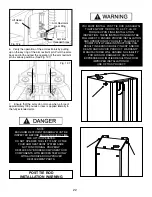

5. If shimming is required, insert the shims as necessary

under the base plate so that when the anchor bolts are

tightened, the posts will be plumb. (See Fig. 5.3)

6. With the foot guards, shims and anchor bolts in place,

tighten by securing the nut to the base then turning 3-5 full

turns clockwise (90 ft-lbs.).

DO NOT

use an impact wrench

for this procedure. (See Fig. 5.4)

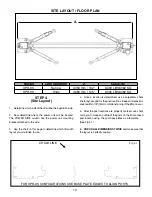

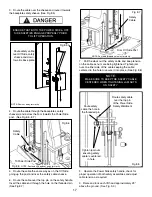

STEP 6

(Installing the OFF SIDE post)

1. Position the OFF SIDE post at the designated chalk

locations and secure post to floor following the same proce-

dures as outlined in STEP 5; Paragraphs 1-6.

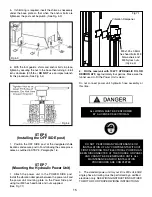

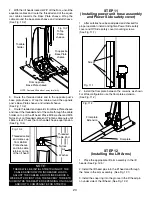

STEP 7

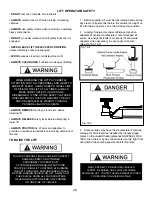

(Mounting the Hydraulic Power Unit)

1. Attach the power unit to the POWER SIDE post.

Install the vibration dampener between the power unit and

the power unit mounting plate on the Power Side post,

using four M8 hex head bolts and nuts supplied.

(See Fig 7.1)

2. Fill the reservoir with 10 WT. HYDRAULIC OIL OR

DEXRON ATF,

approximately four gallons

.

Make sure the

funnel used to fill the Power Unit is clean.

Do not connect power unit hydraulic hose assembly at

this time.

3. The standard power unit for your lift is 220 volt, 60HZ,

single phase. All wiring must be performed by a certified

electrician only. SEE WIRING INSTRUCTIONS AFFIXED

TO MOTOR FOR PROPER WIRING INSTRUCTIONS.

Fig 5.3

Fig 5.4

Fig 7.1.

Vibration Dampener

M8 x1.25 x 35mm

hex head bolts, M8

flat washers and

M8 Nylock nuts

(Qty 4 ea)

ALL WIRING MUST BE PERFORMED

BY A LICENSED ELECTRICIAN.

DO NOT PERFORM ANY MAINTENANCE OR

INSTALLATION OF ANY COMPONENTS WITHOUT

FIRST ENSURING THAT ELECTRICAL POWER HAS

BEEN DISCONNECTED AT THE SOURCE OR PANEL

AND CANNOT BE RE-ENERGIZED UNTIL ALL

MAINTENANCE AND/OR INSTALLATION

PROCEDURES ARE COMPLETED.