If it becomes necessary to clean the heat exchangers because of

carbon deposits, soot, etc., proceed as follows.

NOTE:

Deposits of soot and carbon indicate a problem exists that

needs to be corrected. Action must be taken to correct the problem.

1. Turn off gas and electrical supplies to furnace.

2. Disconnect gas supply at ground joint union using a backup

wrench. Remove gas pipe from gas valve.

3. Disconnect electrical wiring from gas valve.

4. Remove burner/manifold assembly.

a. Remove manifold cover plate and air inlet plate/burner

removal cover.

b. Remove manifold retention plate from front of unit.

c. Loosen screws in manifold retention plate at rear of unit.

d. Disconnect ignition wire at pilot.

e. Remove burner/manifold assembly from unit.

5. Place burner/manifold assembly on flat work surface and

clean burner ports. Use a soft brush to loosen dirt, then

vacuum.

6. GENTLY tap each burner opening with a small, rubber

mallet to loosen any debris in heat exchanger cells.

7. Brush each heat exchanger cell with a nylon heat exchanger

brush with a long, flexible handle.

8. Vacuum each heat exchanger cell and burner box with a

crevice tool attachment.

9. Check position and alignment of ignitor and flame sensor.

(See Fig. 5.)

10. Reinstall burner/manifold assembly and front manifold

retention plate.

11. Tighten screws securing rear manifold retention plate.

12. Reconnect ignition wire at pilot.

13. Reinstall manifold cover plate and air inlet plate/burner

removal cover.

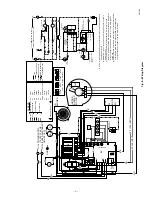

14. Reconnect wiring to gas valve using wiring diagram. (See

Fig. 8.)

15. Apply joint compound (pipe dope) sparingly to male ends

of gas pipe and reinstall gas pipe in gas valve.

NOTE:

Joint compound must be resistant to the action of propane

gas.

16. Reconnect ground joint union.

17. Turn on gas and electrical supplies to furnace.

18. Check gas supply line for leaks.

WARNING:

Never use matches, candles, flame, or

other sources of ignition to check for gas leakage. Use a

soap-and-water solution to check for leaks. Failure to

follow this warning could result in fire, explosion, per-

sonal injury, or death.

19. Check furnace operation through 2 complete operating

cycles. Look through sight-glass in burner enclosure to

check burners. Burner flames should be clear blue, almost

transparent. (See Fig. 4.)

IV.

PILOT ASSEMBLY

Check the pilot assembly and clean if necessary at the beginning of

each heating season. The pilot flame should be high enough for

proper impingement of the ignition electrode/flame sensor and to

light the burners. Remove any accumulation of soot and carbon

from the flame sensor. Check spark ignition electrode gap. (See

Fig. 3, 4, and 5.)

V.

CLEAN CONDENSATE DRAINAGE SYSTEM

1. Disconnect drain tube from bottom of inducer housing and

from vent pipe. (See Fig. 6.)

2. Disconnect condensate drain line.

3. Remove drain/hose assembly from furnace and flush with

water until clean. Ensure drain trap is clean.

Fig. 3—Position of Pilot to Burners

A91347

1

/

8

″

Fig. 4—Burner Flame

A84076

BURNER FLAME

PILOT FLAME

BURNER

MANIFOLD

Fig. 5—Position of Pilot to Ignition Electrode/Flame

Sensor

A91348

3

/

8

″

TO

1

/

2

″

—3—