4. Flush external condensate drain line with water until clean.

5. Reassemble condensate drainage system.

VI.

ELECTRICAL CONTROLS AND WIRING

NOTE:

There may be more than 1 electrical supply to the unit.

Refer to Fig. 7 for filed application wiring and Fig. 8 for unit

wiring. With power disconnected to the unit, check all electrical

connections for tightness. Tighten all screws on electrical connec-

tions. If any smokey or burned connections are found, disassemble

the connection, clean all parts, strip wire, and reassemble properly

and securely.

Reconnect electrical power to the unit and observe unit through 1

complete operating cycle. Electrical controls are difficult to check

without proper instrumentation. A good voltmeter is needed to

check for correct operation of controls and wiring.

If the furnace fails to operate, check the following items before

calling for service:

1. Is thermostat set correctly to "call for heat?"

2. Are electrical and gas supplies on?

3. Are filters clean?

VII.

WINTERIZING

The unit must not be installed, operated, and then turned off and

left off in an unoccupied structure during cold weather when the

temperature drops to 32°F and below. Freezing condensate left in

the furnace will damage the equipment.

If the furnace will be off for an extended period of time in a

structure where the temperature will drop to 32°F or below,

winterize as follows.

1. Mix a solution of equal amounts of ethylene glycol (Pre-

stone II antifreeze/coolant or equivalent) and water.

2. Turn off electrical supply to furnace.

3. Disconnect drain tube from bottom of inducer assembly.

4. Insert funnel in drain tube and pour antifreeze/water solu-

tion into furnace until it is visible at point where condensate

enters open drain.

5. Reconnect drain tube to inducer assembly.

Fig. 6—Condensate Drainage System

A91176

1

″

INDUCER

HOUSING

TUBE

VENT DRAIN

TUBE

TO VENT

TERMINATION

Connect to approved

sewer system per these

instructions and local

codes.

NOTE:

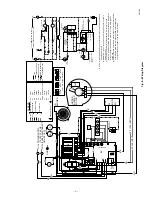

Fig. 7—Heating and Cooling Application Wiring Diagram

A91338

1. Connect Y-terminal as shown for proper cooling operation.

2. If any of the original wire, as supplied, must be replaced,

use same type or equivalent wire.

3. Proper polarity must be maintained for 115-volt wiring.

NOTE :

115-VOLT

FIELD-SUPPLIED

FUSED DISCONNECT

24-VOLT

TERMINAL

BLOCK

TWO-WIRE

HEATING-

ONLY

FOUR

WIRE

THERMOSTAT

TERMINALS

FIELD-SUPPLIED

FUSED DISCONNECT

CONDENSING

UNIT

TWO

WIRE

W

Y

C

G

W

Y

R

GND

GND

FIELD 24-VOLT WIRING

FIELD 115-, 208/230-, 460-VOLT WIRING

FACTORY 24-VOLT WIRING

FACTORY 115-, 208/230-, 460-VOLT WIRING

208/230- OR

460-VOLT

THREE

PHASE

208/230-

VOLT

SINGLE

PHASE

G

R

GND

GND

GND

115-VOLT

SINGLE

PHASE

GND

—4—