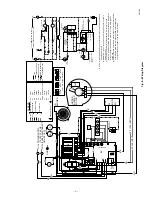

Fig.

8—Wiring

Diagram

A91349

H

M

L

C

INDOOR

BLOWER

MOTOR

BR

BR

CAP

.

I.D.

BLOWER

LEGEND

L1(H)

L2(N)

CIRCULATION

FAN

LOW

TSTAT

24VAC

(115 VAC)

NOTES:

(1) Make field power supply connections to black and white wires capped

with orange wire nuts.

(2) WARNING --- Unit must be grounded. Wiring must conform to N.E.C.

and local codes.

(3) If any of the original wire, as supplied with the furnace, must be

replaced, it must be replaced with wiring material having a temperature

rating of at least 185 C and be a minimum of 16 GA. AWG copper

strand wire.

(4) Connect required motor lead to heat terminal on circuit board to deliver

a temperature rise within the range specified on the rating plate.

Connect unused motor leads to the "M1 & M2" terminals.

LINE Y

24 V

PRINTED CIRCUIT

BOARD WIRING

FACTORY WIRING

FIELD WIRING

ORANGE WIRE NUT

GROUND

BK

BL

BR

GR

OR

RD

RD/BK

VI

WH

YL

BLACK

BLUE

BROWN

GREEN

ORANGE

RED

RED/BLACK STRIPE

VIOLET

WHITE

YELLOW

L

P

ROS

BI

CU

LIMIT

PRESSURE SWITCH

ROLL OUT SWITCH

BLOWER INTERLOCK

CONDENSING UNIT

115 VAC 1 0 60 HZ POWER SUPPLY

(FUSED DISCONNECT ON HOT LEG)

1

2

3

4

60 SEC

90 SEC

120 SEC

DELAY OFF SCREW SETTINGS

150 SEC

MED

HI

GND

N2

HEAT

COOL

N3

D1

N4

C

BI

S1

S2

M2

K1

K2

K2

K3

X

R

Y

C

W

G

CN23-2

CN23-1

CN23-6

LIMIT

CONTROL

TRANSFORMER

CONDENSING

UNIT

PRESSURE SW.

N.O.

N.C.

PS1

PS2

V1

CN23-3

CN23-5

COM.

ST912081005

ELECTRONIC

FAN TIMER

ROS

MV

PV

MV\PV

MV

MV\PV

PV

24V (GNO)

GNO (BURNER)

SPARK

GAS VALVE

HONEYWELL VR8204

PILOT

24V

IGNITION MODULE

HONEYWELL S8600

OR 8660

N1

GNO

MV/PV

MV

G.V.

GND

PV

L1 (H)

L2 (N)

POWER SUPPLY

115 VAC 10 60 HZ

(FUSED DISCONNECT

ON HOT LEG)

GND

VI

ROS

P

BK

BK

CU

T

R

Y

W

G

BI

BK

WH

G

H

C

O

Y

R

L

RD

OR

VI

WH

RD

BK

GR

BK

YL

BL

VI

OR

PILOT

HONEYWELL

S8600

IS

1

2

3

4

5

6

7

8

9

MV

MV/PV

PV

GNO (BURNER)

24V (GNO)

24V

TH-W (OPT)

SPARK

WH

BL

RD/

BK

YL

BC

DELAY OFF

SELECT

A

B

H

E

A

T

C

O

O

L

M1

M2

M3

UNUSED

MOTOR

LEADS

S

1

2

3

4

5

6

1

2

3

4

D1

C

C

X

X

Y

100, 125K INPUT

50, 75K INPUT

BL

YL

INDUCER MOTOR

100,125

FOR 75, 100, 125

50, 75

—5—