BE1-40Q Functional Description

3-3

Specifications, Table 1-1, and on the front panel tap range chart.

TAP Switch

The front panel TAP switch selects the pickup setting (in single-phase vars), depending on the position of

the HI/LOW RANGE switch, as shown in Table 1-1. The TAP switch selects the resistive burden value that

is placed across the output of the internal sensing input CT. The resistive burden establishes the scaling

of the internal signal that represents the input current value.

Transducer

The transducer consists of a multiplier and integrator. The multiplier and associated control circuits produce

an output that is representative of the product of the scaled current input and the scaled, phase-shifted

voltage input signal. The output waveform of the multiplier is an instantaneous value; therefore, the output

is integrated to develop a signal that represents the average var value. The integrator response time is a

function of the pickup multiple, as shown in Section 1,

Specifications.

Comparator

The signal representing the single-phase var value is compared with the pickup reference. When the

reference value is exceeded, the PICKUP LED indicator is illuminated and timing is initiated.

Timing

A definite time delay is initiated when the monitored var level exceeds the pickup reference. A calibrated

frequency generating circuit, in conjunction with counter circuits and the front panel TIME DELAY

thumbwheel switches, establishes the definite time delay interval.

Time delay is adjustable from 0.1 to 9.9 seconds in 0.1 second intervals. A setting of 00 enables

instantaneous (no intentional time delay) operation. Timing is instantaneously reset if the var level reduces

to less than the pickup setting.

For a complete description of timing accuracy, refer to

Specifications in Section 1.

Outputs

Defined by the style number, the output relay may have either a normally open (NO) or normally closed (NC)

configuration. The normally open output contact option is required when current operated targets are

desired.

In addition, an auxiliary output contact may be provided which is specified by style number as NO, NC, or

SPDT. If an auxiliary contact is provided, then the power supply status output is not available.

Targets

A magnetically-latching target indicator may be provided for the output contact as an option. This target is

actuated upon relay trip and may be either internally operated or current operated. An internally operated

target may be specified with either a normally open or normally closed output contact. When a current

operated target is desired, the output contact must be specified with a normally open configuration. The

current operated target requires a minimum of 0.2 amps flowing through the output relay contacts. The

target indicator must be reset with the manual target reset lever.

PUSH-TO-ENERGIZE OUTPUT Pushbutton

A small pushbutton switch may be provided as an option to allow testing the primary output contact and (if

present) the auxiliary output contact. To prevent accidental operation, the pushbutton is recessed behind

the front panel and is depressed by inserting a thin, non-conducting rod through an access hole in the front

panel.

Содержание BE1-40Q

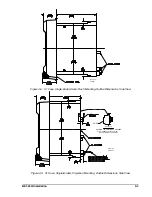

Страница 13: ...2 2 BE1 40Q Human Machine Interface Figure 2 1 Location of Controls and Indicators ...

Страница 19: ...4 2 BE1 40Q Installation 2 02 01 D1427 01 Figure 4 1 S1 Case Outline Dimensions Front View ...

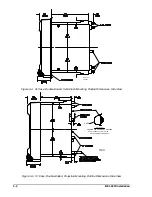

Страница 22: ...BE1 40Q Installation 4 5 Figure 4 6 S1 Case Outline Dimensions Rear View ...

Страница 25: ...4 8 BE1 40Q Installation Figure 4 10 Sensing Input Connections Figure 4 11 Output Connections ...

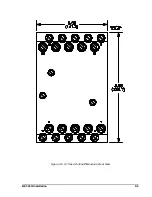

Страница 35: ...5 8 BE1 40Q Setting and Testing Figure 5 4 Blank Graph ...