page 44

page 44

page 44

page 44

page 44

275B SER

800-00152

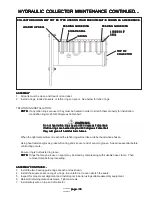

Figure 8

Figure 8

Figure 8

Figure 8

Figure 8

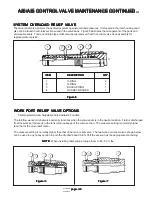

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

A20/A35 CONTROL VALVE MAINTENANCE CONTINUED...

SERVICE INSTRUCTIONS FOR VA/VG REMOTE CONTROL OPERATORS

SERVICE INSTRUCTIONS FOR VA/VG REMOTE CONTROL OPERATORS

SERVICE INSTRUCTIONS FOR VA/VG REMOTE CONTROL OPERATORS

SERVICE INSTRUCTIONS FOR VA/VG REMOTE CONTROL OPERATORS

SERVICE INSTRUCTIONS FOR VA/VG REMOTE CONTROL OPERATORS

Read these instructions carefully. Failure to follow these procedures can result in poor performance and/or product

failure. Make sure all work is done in a clean area.

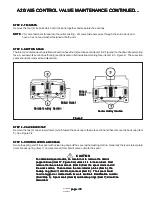

SECTION DISASSEMBLY -

SECTION DISASSEMBLY -

SECTION DISASSEMBLY -

SECTION DISASSEMBLY -

SECTION DISASSEMBLY - SEE FIGURE 8.

1. Remove cap screws (8) from both ends of the valve section.

2. Remove end caps (6), seal (10) and end cap tube (11) from each end of casting.

3. Remove seal retainer (2) and seals (1 & 10) from the clevis end of the spool assembly.

4. Remove spool and spring package assembly from valve section. Remove seal retainer (2) and seals (1 & 10) to

replace seals.

5. If stripper bolt (3) must be removed from the spool for replacement of parts, it may be necessary to apply heat to

the hex nut and stripper bolt to loosen adhesive that was applied to the threads. Use heat carefully to avoid

warping spool.

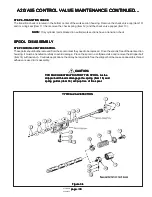

PREPARATION OF PARTS

PREPARATION OF PARTS

PREPARATION OF PARTS

PREPARATION OF PARTS

PREPARATION OF PARTS

1. Clean adhesive from threads of spool, stripper bolt, housing, cap screw holes and hex nut with Loctite Chisel

Gasket Remover.

2. Wash all parts in solvent to remove grease and oil. Blow dry.

SECTION ASSEMBLY -

SECTION ASSEMBLY -

SECTION ASSEMBLY -

SECTION ASSEMBLY -

SECTION ASSEMBLY - SEE FIGURE 8

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Failure to follow these recommended assembly

Failure to follow these recommended assembly

Failure to follow these recommended assembly

Failure to follow these recommended assembly

Failure to follow these recommended assembly

instructions can result in poor performance and/or

instructions can result in poor performance and/or

instructions can result in poor performance and/or

instructions can result in poor performance and/or

instructions can result in poor performance and/or

failure of the product. Product should be thoroughly

failure of the product. Product should be thoroughly

failure of the product. Product should be thoroughly

failure of the product. Product should be thoroughly

failure of the product. Product should be thoroughly

tested to ensure proper operation before the valve

tested to ensure proper operation before the valve

tested to ensure proper operation before the valve

tested to ensure proper operation before the valve

tested to ensure proper operation before the valve

is put into service.

is put into service.

is put into service.

is put into service.

is put into service.