page 27

page 27

page 27

page 27

page 27

275B SER

800-00152

CLEANING THE RESERVOIR

CLEANING THE RESERVOIR

CLEANING THE RESERVOIR

CLEANING THE RESERVOIR

CLEANING THE RESERVOIR

1. Clean area around inspection cover on reservoir, and then remove cover.

2. Remove suction strainer(s) from inside reservoir. Clean with a solvent. (see Figure 2).

3. Remove all dirt and sediment from inside reservoir.

4. Remove filler cap and clean filler cap screen. Check for damage. If damaged, replace screen.

5. After everything in and around reservoir is completely clean, replace suction strainer(s), drain plug, filler cap, and

inspection cover.

FILLING THE RESERVOIR

FILLING THE RESERVOIR

FILLING THE RESERVOIR

FILLING THE RESERVOIR

FILLING THE RESERVOIR

1. With drain plug in place and tightened, refill reservoir with recommended hydraulic oil. Be sure filler cap screen is in

place and clean.

2. Start engine, running it slowly until new oil circulates throughout the system.

3. With all control valves in neutral, run engine until pump quiets down, then add more hydraulic oil, if necessary.

4. As an operator works the booms and grapple, add more hydraulic oil as needed to maintain proper level in reservoir.

This will work air out of system and prevent cavitation, which is caused by air bubbles in hydraulic oil as it passes

through a pump.

5. Check hydraulic oil level again after loader has been operating for an hour or two. Add more hydraulic oil if needed.

HYDRAULIC RESERVOIR MAINTENANCE CONTINUED...

HYDRAULIC RESERVOIR MAINTENANCE CONTINUED...

HYDRAULIC RESERVOIR MAINTENANCE CONTINUED...

HYDRAULIC RESERVOIR MAINTENANCE CONTINUED...

HYDRAULIC RESERVOIR MAINTENANCE CONTINUED...

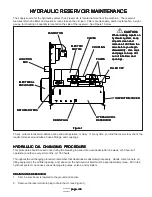

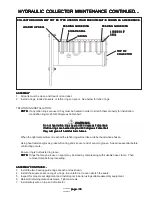

TOP VIEW OF RESERVOIR

TOP VIEW OF RESERVOIR

TOP VIEW OF RESERVOIR

TOP VIEW OF RESERVOIR

TOP VIEW OF RESERVOIR

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

INSPECTION

INSPECTION

INSPECTION

INSPECTION

INSPECTION

COVER

COVER

COVER

COVER

COVER

FILLER CAP

FILLER CAP

FILLER CAP

FILLER CAP

FILLER CAP

When making repairs on

When making repairs on

When making repairs on

When making repairs on

When making repairs on

hydraulic system, keep

hydraulic system, keep

hydraulic system, keep

hydraulic system, keep

hydraulic system, keep

all parts clean and

all parts clean and

all parts clean and

all parts clean and

all parts clean and

remove all dirt from the

remove all dirt from the

remove all dirt from the

remove all dirt from the

remove all dirt from the

area before you begin

area before you begin

area before you begin

area before you begin

area before you begin

disassembly. Use caps

disassembly. Use caps

disassembly. Use caps

disassembly. Use caps

disassembly. Use caps

and plugs to keep dirt

and plugs to keep dirt

and plugs to keep dirt

and plugs to keep dirt

and plugs to keep dirt

out of tubelines and

out of tubelines and

out of tubelines and

out of tubelines and

out of tubelines and

openings.

openings.

openings.

openings.

openings.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

HYDRAULIC OIL

HYDRAULIC OIL

HYDRAULIC OIL

HYDRAULIC OIL

HYDRAULIC OIL

RESERVOIR

RESERVOIR

RESERVOIR

RESERVOIR

RESERVOIR

ELECTRICAL

ELECTRICAL

ELECTRICAL

ELECTRICAL

ELECTRICAL

ENCLOSURE

ENCLOSURE

ENCLOSURE

ENCLOSURE

ENCLOSURE

RETURN FILTERS

RETURN FILTERS

RETURN FILTERS

RETURN FILTERS

RETURN FILTERS

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC

MOTOR

MOTOR

MOTOR

MOTOR

MOTOR

PUMPS

PUMPS

PUMPS

PUMPS

PUMPS

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

FAN MOTOR

VALVES

VALVES

VALVES

VALVES

VALVES

COUPLING

COUPLING

COUPLING

COUPLING

COUPLING

SIGHT GAGE

SIGHT GAGE

SIGHT GAGE

SIGHT GAGE

SIGHT GAGE

SUCTION STRAINERS

SUCTION STRAINERS

SUCTION STRAINERS

SUCTION STRAINERS

SUCTION STRAINERS

(inside reservoir)