Manual 2100-365

Page 14

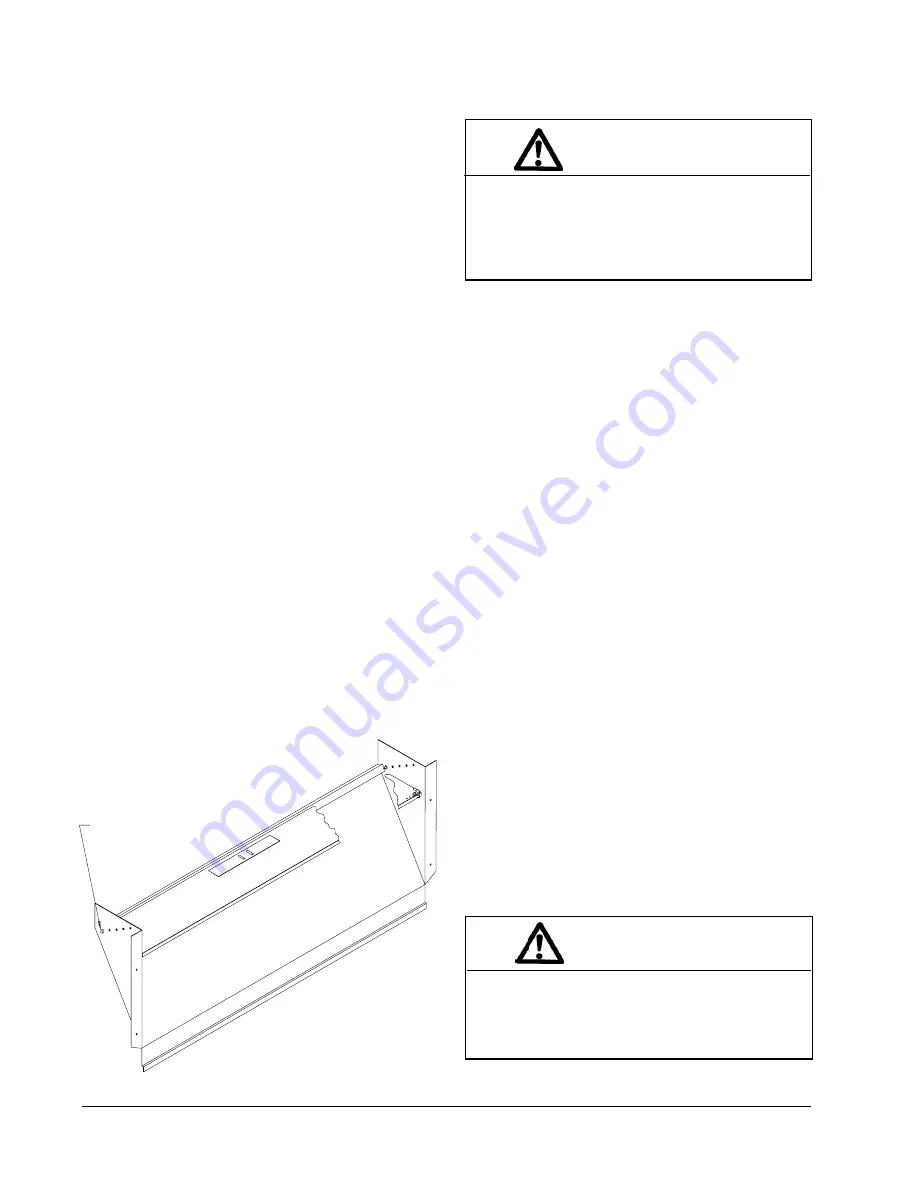

13. FRESH AIR INTAKE

All units are built with fresh air inlet slots punched in

the service panel.

If the unit is equipped with a fresh air damper

assembly, the assembly is shipped already attached to

the unit. The damper blade is locked in the closed

position. To allow the damper to operate, the

maximum and minimum blade position stops must be

installed. See Figure 9.

All capacity, efficiency and cost of operation

information as required for Department of Energy

“Energyguide” Fact Sheets is based upon the fresh air

blank-off plate in place and is recommended for

maximum energy efficiency.

The blank-off plate is available upon request from the

factory and is installed in place of the fresh air

damper shipped with each unit.

One of several other ventilation options may be

installed. Refer to model number and/or

supplemental installation instructions.

14. CONDENSATE DRAIN

A plastic drain hose extends from the drain pan at the

top of the unit down to the unit base. There are

openings in the unit base for the drain hose to pass

through. In the event the drain hose is connected to a

drain system of some type, it must be an open or

vented type system to assure proper drainage.

15. WIRING – MAIN POWER

FIGURE 9

FRESH AIR DAMPER

BLADE IS

LOCKED CLOSED

FOR SHIPPING

MIS-938

Refer to unit rating plate for wire sizing information

and maximum fuse or “HACR” type circuit breaker

size. Each outdoor unit is marked with a “Minimum

Circuit Ampacity”. This means that the field wiring

used must be sized to carry that amount of current.

All models are suitable only for connection with

copper wire. Each unit and/or wiring diagram will be

marked - “

Use Copper Conductors Only

”. These

instructions

must be

adhered to. Refer to the

National Electrical Code (NEC) for complete current

carrying capacity data on the various insulation

grades of wiring material. All wiring must conform

to NEC and all local codes.

The electrical data lists fuse and wire sizes (75° C

copper) for all models.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or “HACR” type circuit breaker that is to

be used with the equipment. The correct size must be

used for proper circuit protection and also to assure

that there will be no nuisance tripping due to the

momentary high starting current of the compressor

motor.

The disconnect access door on this unit may be

locked to prevent unauthorized access to the

disconnect. To convert for the locking capability

bend the tab located in the bottom left hand corner of

the disconnect opening under the disconnect access

panel straight out. This tab will now line up with the

slot in the door. When shut a padlock may be placed

through the hole in the tab preventing entry.

See “Start Up” section for important information on

three phase scroll compressor start ups.

WARNING

For your personal safety, turn off electric power

at service entrance panel before making any

electrical connections. Failure to do so could

result in electric shock or fire.

WARNING

Failure to provide an electrical power supply

shut-off means could result in electric shock or

fire.

Содержание WG421

Страница 8: ...Manual 2100 365 Page 5 MIS 1352 FIGURE 1 UNIT DIMENSIONS...

Страница 12: ...Manual 2100 365 Page 9 FIGURE 4 MOUNTING INSTRUCTIONS MIS 1472...

Страница 15: ...Manual 2100 365 Page 12 FIGURE 8 COMMON WALL MOUNTING INSTALLATIONS MIS 1474...

Страница 20: ...Manual 2100 365 Page 17 FIGURE 11 LOW VOLTAGE WIRING MIS 1162...

Страница 21: ...Manual 2100 365 Page 18 FIGURE 12 GAS PIPE CONNECTION MIS 1478...

Страница 29: ...Manual 2100 365 Page 26 26 LIGHTING AND SHUTDOWN INSTRUCTIONS FIGURE 14 INSTRUCTION LABEL...

Страница 34: ...Manual 2100 365 Page 31 FIGURE 18 460 VOLT BLOWER MOTOR WIRING OPTIONS MIS 1487 A B C...

Страница 41: ...Manual 2100 365 Page 38...

Страница 42: ...Manual 2100 365 Page 39...

Страница 43: ...Manual 2100 365 Page 40...

Страница 44: ...Manual 2100 365 Page 41...

Страница 45: ...Manual 2100 365 Page 42...

Страница 46: ...Manual 2100 365 Page 43...

Страница 47: ...Manual 2100 365 Page 44...

Страница 48: ...Manual 2100 365 Page 45...

Страница 49: ...Manual 2100 365 Page 46...

Страница 50: ...Manual 2100 365 Page 47...

Страница 51: ...Manual 2100 365 Page 48...

Страница 52: ...Manual 2100 365 Page 49...