Manual

2100-549G

Page

21 of 59

INSTALLATION INSTRUCTIONS

MOUNTING THE UNIT

The wall sleeve is attached to the I-TEC unit from the

outside of the building. See Figures 11A & 11B. Refer

to wall sleeve Manual 2100-562 supplied with sleeve.

Following are the steps for attaching the I-TEC to the

wall sleeve.

1.

Lift the unit into place making sure that it is

aligned side to side.

2.

Push the unit back until the rear panel touches the

sleeve gasket.

3.

This unit must be level from side to side and from

front to back. If adjustments are necessary, shim

up under the base rails with sheets of metal or any

substance not affected by moisture.

4.

Attach the sleeve to the unit using the ten (10) ¾"

long self-tapping screws supplied with the sleeve.

5.

The exhaust sleeve has three (3) ¾" long screw slots

in each side flange. Line these up with the screw

engagement holes in the fan panel. Attach using six

(6) ¾" long pointed sheet metal screws supplied

with the sleeve. Extend the sleeve out until it is

flush with the louver grill attachment angles.

6.

Lock the sleeve in place using two (2) ½" long

pointed sheet metal screws on each side by

shooting through the slot into a pre-punched hole.

7.

A bottom trim piece is shipped loose for

installation beneath the doors. Attach the trim

piece to the unit with screws provided.

8.

The compressor is secured to the base with two

(2) bolts for shipping. Both bolts are identified

with a tag. Remove shipping bolts (Figure 5).

WIRING – MAIN POWER

Refer to the unit rating plate and/or Table 2 for wire sizing

information and maximum fuse or “HACR Type” circuit

breaker size. Each unit is marked with a “Minimum Circuit

Ampacity”. This means that the field wiring used must be

sized to carry that amount of current. Depending on the

installed KW of electric heat, there may be two field power

circuits required. If this is the case, the unit serial plate will

so indicate. All models are suitable only for connection

with copper wire. Each unit and/or wiring diagram will be

marked “Use Copper Conductors Only suitable for at least

75°C”.

THESE INSTRUCTIONS MUST BE

ADHERED TO.

Refer to the National Electrical Code

(NEC) for complete current carrying capacity data on the

various insulation grades of wiring material. All wiring

must conform to NEC and all local codes.

The electrical data lists fuse and wire sizes (75°C copper)

for all models, including the most commonly used heater

sizes. Also shown are the number of field power circuits

required for the various models with heaters.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or “HACR Type” circuit breaker that is to

be used with the equipment. The correct size must be

used for proper circuit protection, and also to assure that

there will be no nuisance tripping due to the momentary

high starting current of the compressor motor.

See “

START UP

” section for information on three phase

scroll compressor start-ups.

The field wiring conduit connections are located on the top

right-hand corner of the unit with a wire raceway to feed

the wires down to the circuit breaker(s). See Figure 12.

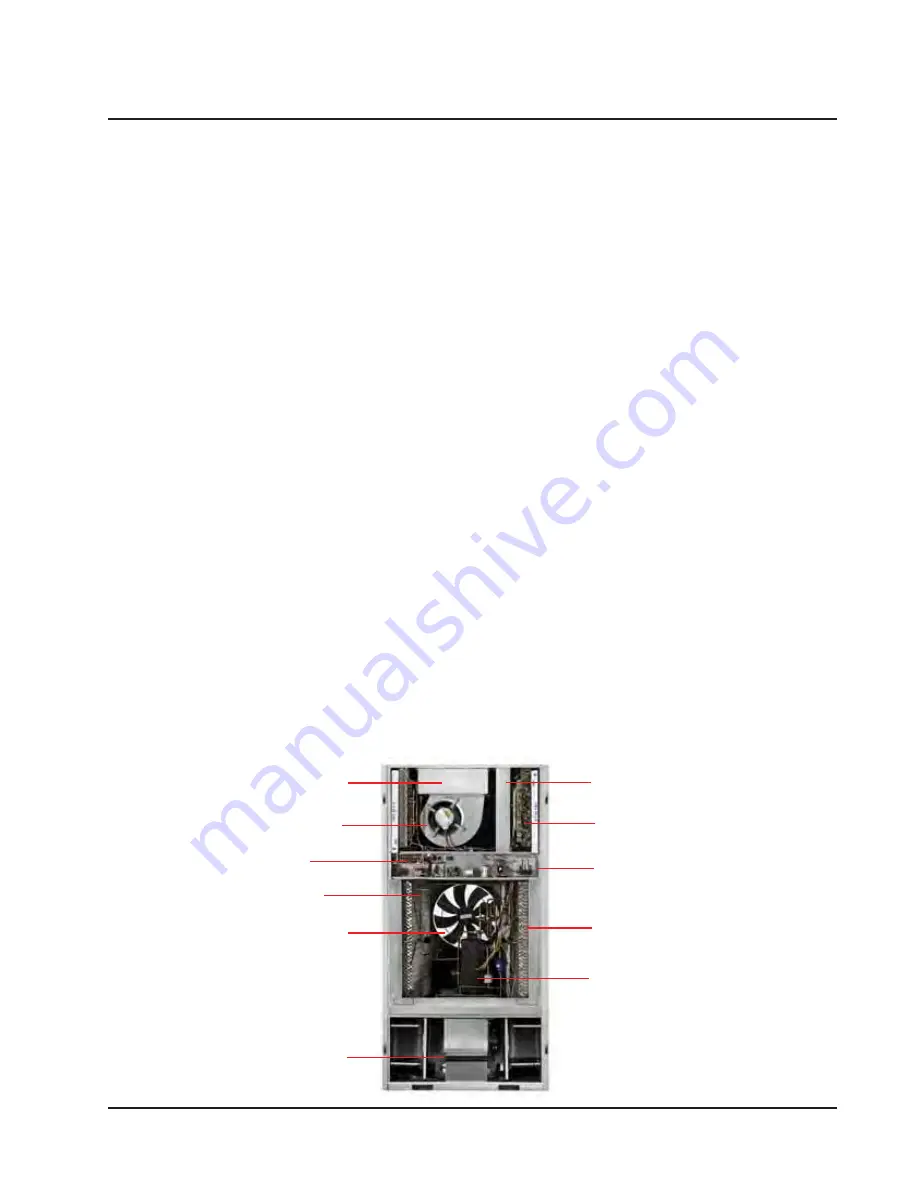

FIGURE 12

COMPONENT LOCATION

VENT OPTION

CONDENSER COIL

WIRE RACEWAY

COMPRESSOR

EVAPORATOR COIL

CONTROL PANEL

ELECTRIC HEAT

INDOOR BLOWER

OUTDOOR FAN

LOW VOLTAGE

REFRIGERANT PORT