8 Checkout Procedures

8.1 Periodic Checkout Requirements

This section lists the schedule of checkout procedures and describes where each procedure is documented. Checkouts must

be performed as described. Results should be recorded and kept in the appropriate place (for example, near the machine,

and/or in a technical file).

Banner Engineering highly recommends performing the System checkouts as described. However, a qualified person (or

team) should evaluate these generic recommendations considering their specific application and determine the appropriate

frequency of checkouts. This will generally be determined by a risk assessment, such as the one contained in ANSI B11.0.

The result of the risk assessment will drive the frequency and content of the periodic checkout procedures and must be

followed.

At every shift change, power-up, and machine setup change

, perform the Daily checkout. This checkout may be

performed by a Designated or Qualified Person (see the Daily Checkout Card for the procedure).

Semi-annually

, the Scanner and its interface to the guarded machine should be thoroughly checked out. This checkout must

be performed by a Qualified Person (see the Semi-Annual Checkout Card for the procedure). A copy of these test results

should be posted on or near the machine.

When changes are made to the System

(either a new configuration of the Scanner or changes to the machine), perform

the Commissioning Checkout.

WARNING:

•

Verify the proper operation of this SX Series Safety Laser Scanner

•

Failure to verify the proper operation, on a regular basis, can result in undetected problems, which

if not corrected, can result in serious injury or death.

•

It is the user’s responsibility to verify proper operation on a regular basis.

Study each procedure in its entirety, to understand each step thoroughly before beginning. Refer all questions to a Banner

on p. 125). Checkouts must be performed as detailed and results must be recorded

and kept in the appropriate place (e.g., near the machine, and/or in a technical file). This must include a printout of the SX’s

configuration and the shape of all Safety Zones.

Additional factors and checks may be required that are dependent on the application, machine, or local regulations and laws.

A user risk assessment will determine what these additional factors and checks will be and should be incorporated with the

checkouts below. For easy reference, print out the procedures and post them near the machine/application.

8.2 Schedule of Checkouts

Checkout cards and this manual can be downloaded at

http://www.bannerengineering.com

.

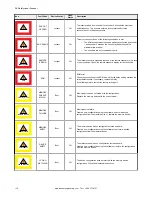

Checkout

Procedure

When to Perform

Where to Find the Procedure

Who Must Perform

the Procedure

Trip Test

At Installation

Any time the SX, the guarded machine, or any part

of the application is altered.

on p. 65

Qualified Person

Commissioning

Checkout

At Installation

When changes are made to the SX (for example,

either a new configuration of the SX or changes to

the guarded machine).

Perform a Commissioning Checkout

Qualified Person

Shift/Daily Checkout

At each shift change

Machine setup change

After the SX is powered up

During continuous machine run periods, this

checkout should be performed at intervals not to

exceed 24 hours.

Daily Checkout Card

)

A copy of the checkout results should be recorded

and kept in the appropriate place (for example, near

or on the machine, in the machine's technical file).

Designated Person or

Qualified Person

Semi-Annual

Checkout

Every six months following SX installation, or after

changes are made to the SX (either a new

configuration of the SX or changes to the

machine).

Semi-Annual Checkout Card

)

A copy of the checkout results should be recorded

and kept in the appropriate place (for example, near

or on the machine, in the machine's technical file).

Qualified Person

SX Safety Laser Scanner

www.bannerengineering.com - Tel: + 1 888 373 6767

101

Содержание SX5-B

Страница 135: ...Index M mute sensor 69 mute switch 69 ...