16 / 20

0006081531_201203

ENGLISH

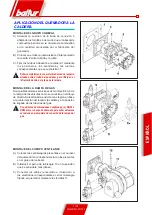

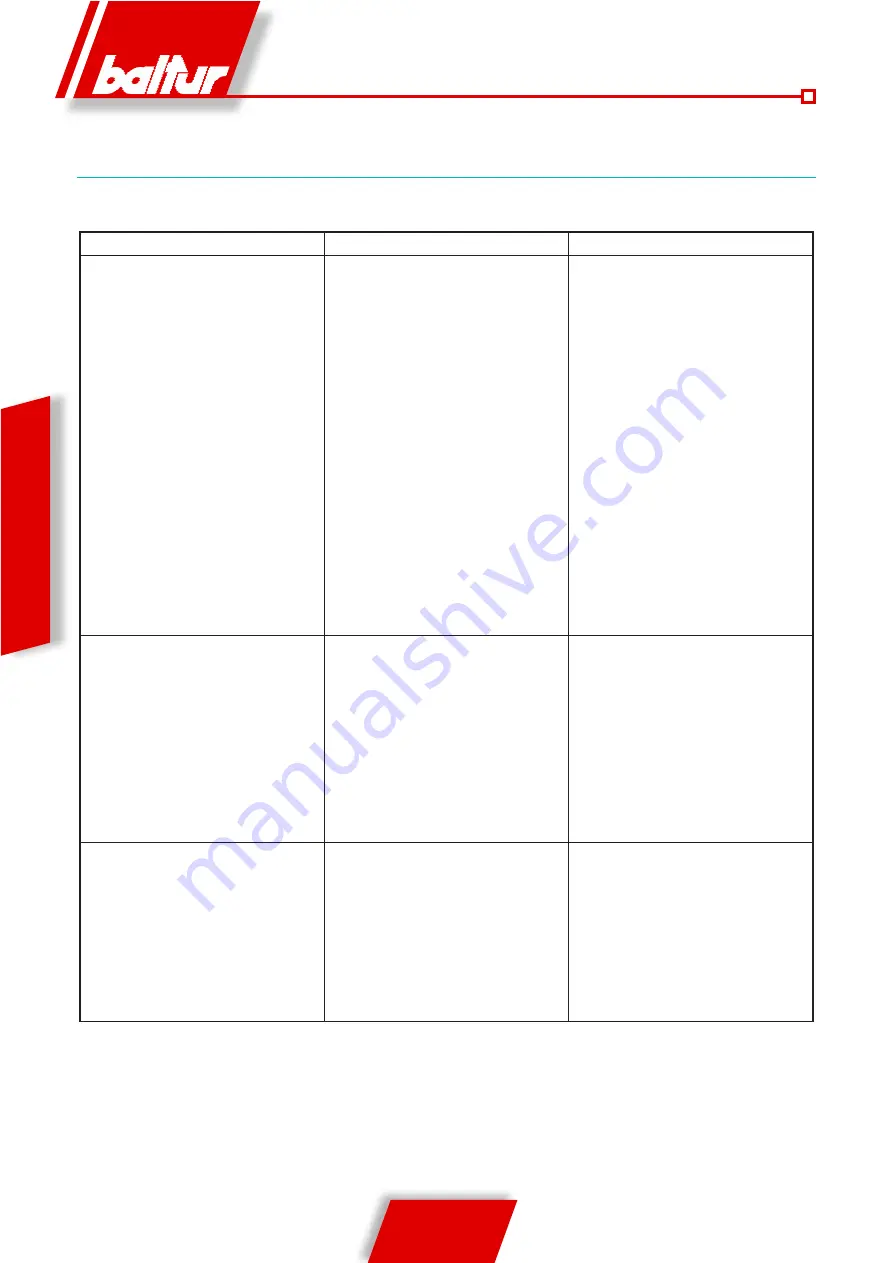

HOW TO FIND THE CAUSES OF IMPROPER OPERATION OF TWO-STAGE GAS BURNERS

AND HOW TO RECTIFY THEM

PROBLEM

POSSIBLE CAUSE

SOLUTION

The equipment goes into “lock-out” with

the flame (red light on). Mal-

functioning is due to the flame

control device.

1) Disturbance to ionisation current from

ignition transformer.

2) Inefficient flame sensor (ionisation

probe).

3) Flame sensor (ionisation probe) position

incorrect.

4) Ionisation probe or relative earth cable.

5) Flame sensor electrical connection

cut-off.

6) Inefficient draught or fumes passage

blocked.

7) Flame disk or combustion head dirty

or worn.

8) Faulty equipment.

9) No ionisation.

1) Invert the ignition transformer power

supply (230V side) and check using an

analogue micro-ammeter.

2) Replace the flame sensor

3) Correct the position of the flame sensor,

and then check its efficiency by connect-

ing the analogue micro-ammeter.

4) Check visually and using the instrument.

5) Restore the connection.

6) Ensure that the boiler fumes passage

and chimney connection are free.

7) Visually check and replace, if necessary.

8) Replace.

9) If the “earth” of the equipment is not

efficient, the ionisation current cannot

be checked. Check the efficiency of the

“earth” at the terminal concerned in the

equipment and at the “earth” connection

of the electric system.

The equipment goes into “lock-out”,

gas flows out, but there is no flame

(red light on).

F a u l t i n i g n i t i o n

circuit.

1) Fault in ignition circuit.

2) Ignition transformer cable discharges

to earth.

3) Ignition transformer cable discon-

nected.

4) Faulty ignition transformer.

5) The distance between electrode and

earth is incorrect.

6) Isolator dirty, therefore the electrode

discharges to earth

1) Check the ignition transformer power

supply (230V) and high voltage circuit

(electrode to earth or isolator broken

under locking terminal).

2) Replace.

3) Connect.

4) Replace.

5) Position at the correct distance

6) Clean or change the isolator or electrode.

The equipment goes into “lock-out”,

gas flows out, but there is no flame

(red light on)

1) Air/gas ratio incorrect.

2) Gas piping has not been properly bled

of air (in the case of first ignition).

3) The gas pressure is insufficient or

excessive.

4) Air passage between disk and head

too narrow.

1) Correct the air/gas ratio (there

is probably too much air or very

little gas)

2) Bleed the gas pipe again, taking

great care.

3) Check the gas pressure value at

the time of ignition (use a water

pressure gauge, if possible).

4) Adjust the disk/head opening.

Содержание TBG 85 ME

Страница 2: ......

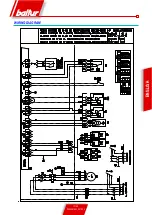

Страница 19: ...17 20 0006081531_201203 ENGLISH WIRING DIAGRAM...

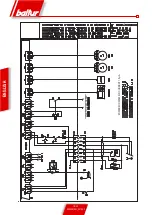

Страница 20: ...18 20 0006081531_201203 ENGLISH START FOR RECORDER MINIMUM IONISATION CURRENT 1 5 A...

Страница 39: ...17 20 0006081531_201203 ESPA OL ESQUEMA EL CTRICO...

Страница 40: ...18 20 0006081531_201203 ESPA OL ARRANQUE PARA REGISTRADOR CORRENTE M NIMA DE IONIZACI N 1 5 A...

Страница 59: ...17 20 0006081531_201203 FRAN AIS SCHEMA ELECTRIQUE...

Страница 60: ...18 20 0006081531_201203 FRAN AIS MARCHE POUR ENREGISTREUR COURANT D IONISATION MINIMUM 1 5 A...

Страница 79: ...17 20 0006081531_201203 T RK E ELEKTR K EMASI...

Страница 80: ...18 20 0006081531_201203 T RK E REG LAT R N BA LATMA M N MUM YON ZASYON AKIMI 1 5 A...

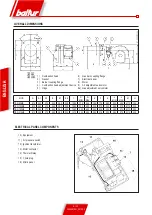

Страница 84: ...2 20 0006081531_201203 PYCCK BALTUR a b c a b c d e f g...

Страница 85: ...3 20 0006081531_201203 PYCCK 2 RC a b c d e a b a b c d...

Страница 89: ...7 20 0006081531_201203 PYCCK A 5 6 B 3 2 C 4 1 7 8 8a 9 DN65 DN80 A B 10 C 11...

Страница 90: ...8 20 0006081531_201203 N 0002910950n2 PYCCK EN676 1 2 3 4 5 6 7 8 9 10 11 12 13 14...

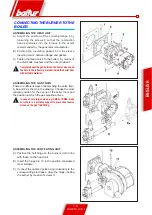

Страница 92: ...10 20 0006081531_201203 A B farfallaTBG ME PYCCK 3 RESET 4 B LAMTEC BT 3xx BT 3xx 30 2 200 999 BT 3xx...

Страница 94: ...12 20 0006081531_201203 ioniz_BT3xx PYCCK 1 4 A 13 14 15...

Страница 97: ...15 20 0006081531_201203 figura 1 figura 2 figura 4 figura 3 PYCCK 2 1 3 4 5 8 6 8 9 0002934691 7 2...

Страница 99: ...17 20 0006081531_201203 PYCCK...

Страница 100: ...18 20 0006081531_201203 PYCCK 1 5 A...

Страница 101: ...19 20 0006081531_201203 PYCCK 0 4 20 A...

Страница 104: ...2 20 0006081531_201203 a b c a b c d e f g I...

Страница 105: ...3 20 0006081531_201203 2 RC a b c d e a b a b c d I...

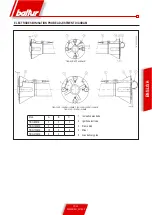

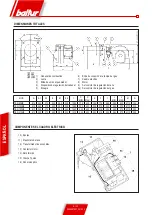

Страница 109: ...7 20 0006081531_201203 5 6 2 3 7 4 1 8 8A 9 DN65 DN80 10 11...

Страница 110: ...8 20 0006081531_201203 N 0002910950n2 EN676 1 2 3 4 5 6 7 8 9 10 11 12 13 14...

Страница 111: ...9 20 0006081531_201203 1 4 1 2 3 7 2 4 5 3 6 7 9 5 10 mm 8 5 9mm IP 54 CEI EN60529 5Nm 4 1 8 4 7 5 9 2 3 4 5 1...

Страница 112: ...10 20 0006081531_201203 A B farfallaTBG ME A B LAMTEC BT 3xx BT 3xx 30 3 3 2 200 2 999 BT 3xx 3 3 4...

Страница 113: ...11 20 0006081531_201203 display lamtec BT3xx 3 4 1 2 5 1 2 3 4 5 O BT3xx BT 3xx 200 CO...

Страница 114: ...12 20 0006081531_201203 ioniz_BT3xx 1 4 A...

Страница 117: ...15 20 0006081531_201203 figura 1 figura 2 figura 4 figura 3 2 2 1 3 4 5 8 6 8 9 0002934691 7 2...

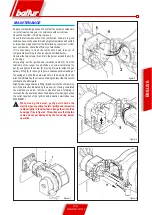

Страница 118: ...16 20 0006081531_201203 1 2 3 4 5 6 7 8 9 1 230V 2 3 4 5 6 7 8 9 1 2 3 4 5 6 1 230V 2 3 4 5 6 1 2 3 4 1 2 3 4...

Страница 119: ...17 20 0006081531_201203...

Страница 120: ...18 20 0006081531_201203 1 5 A...

Страница 121: ...19 20 0006081531_201203 0 4 20 mA...

Страница 123: ......