ENGLISH

23 / 42

0006160060_201802

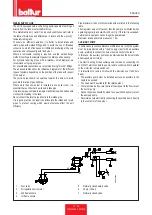

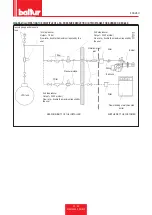

NATURAL GAS IGNITION AND REGULATION

ADJUSTING POWER UPON FIRST START-UP

• If fitted, open the safety valve flow rate regulator fully.

• Now, turn the switch -1 on. This powers on the control box and

the programmer turns on the burner as described in chapter :

"OPERATION DESCRIPTION".

• During preventilation, make sure that the air pressure control

switch changes its status (from the closed position without pressure

measurement to the closed position with pressure measurement).

• If the air pressure switch does not detect sufficient pressure, the

ignition transformer is not switched on, nor are the gas valves, and

so the equipment is stopped in “lock-out” mode (warning light 7).

• On first switching on repeated “lock-outs” may occur due to the

following reasons:

- The bleeding-out of air from the gas piping was not performed

correctly and so there is not enough gas to provide a stable

flame.

- The “lock-out” with flame present may be caused by its

instability in the ionisation area, due to an incorrect air/gas

ratio.

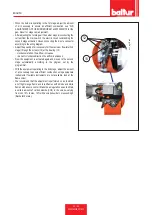

- Correct the air flow rate supplied in the first stage, using the

screw(s) -11, near the bearing -12.

In clockwise rotation the air flow increases

In anticlockwise rotation the air flow decreases

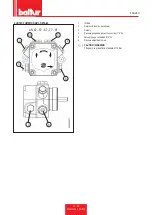

SECOND STAGE POWER REGULATION.

• After adjusting the regulation for the first ignition, turn off the burner

and close the electrical circuit commanding inclusion of the second

stage. Set the switch on the printed circuit to the second stage

position.

•

Check that the electric servomotor second stage gas flow rate

regulation cam is positioned at 130°.

• Activate the burner again closing the main switch -1 on the synoptic

panel. The burner turns on and goes automatically to second stage.

With the aid of appropriate instruments, attend to the regulation

of the air and gas flow according to the procedures subsequently

described:

- To regulate the gas flow operate the valve pressure regulator.

Consult the instructions related to the single stage gas valve

model installed. Avoid keeping the burner running if the heating

capacity is greater than the maximum amount allowed for the

boiler, to avoid damaging it.

• Check the combustion parameters with appropriate instruments

(CO2 MAX=10% O2 MIN= 3% CO MAX=0.1%)

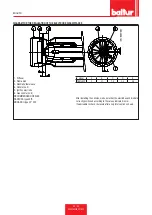

FIRST STAGE POWER REGULATION.

After regulation of the burner in the second stage, return the burner

to the first stage. Set the switch on the printed circuit to the first stage

position by disabling the 4-pole green connector, without changing

the adjustment of the gas valve already performed in previous step.

• Set the first stage gas flow rate to the needed value, as described

above.

• If necessary, correct the combustion air supply adjusting the

screw/s (12) as described previously.

• Check the combustion parameters in the 1st stage with appropriate

instruments (CO2 MAX=10% O2 MIN= 3% CO MAX=0.1%)

• The air pressure switch prevents the opening of the gas valves

if the air pressure is not the foreseen one. The pressure switch

must therefore be adjusted to intervene closing the contact when

the air pressure in the burner reaches a sufficient value. If the

air pressure switch does not detect a pressure greater than that

calibrated, the equipment runs through its cycle but does not

switch on the ignition transformer and the gas valves do not open,

consequently the burner “locks-out”. To ensure correct operation of

the air pressure switch you must, with burner lit and in first stage,

increase its regulation value until the burner triggers after which

it must immediately “lock out”. Release the burner by pushing

the appropriate button -9 and readjust the pressure switch to a

sufficient value to detect the existing air pressure during the pre-

ventilation phase of the first stage.

Содержание 56470010

Страница 2: ......

Страница 4: ...ITALIANO 2 42 0006160060_201802 ITALIANO Schemi elettrici 41 ...

Страница 43: ...ITALIANO 41 42 0006160060_201802 SCHEMI ELETTRICI ...

Страница 46: ...ENGLISH 2 42 0006160060_201802 ENGLISH Wiring diagrams 41 ...

Страница 85: ...ENGLISH 41 42 0006160060_201802 WIRING DIAGRAMS ...

Страница 87: ......