ENGLISH

17 / 42

0006160060_201802

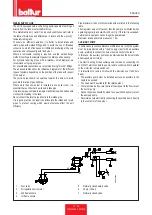

DIESEL SUPPLY LINE

The unit is equipped with a self-priming pump capable of sucking oil

directly from the tank also for the first fill-up.

This statement is only valid if the required conditions exist (refer to

the table of distances and differences in levels and the viscosity -

temperature diagram).

To ensure an efficient operation, it is better to install intake and

return pipes with welded fittings and to avoid the use of threaded

connections, which often cause air infiltration interfering with pump

operation and consequently with the burner.

Where a removable coupling is required, use the welded flange

method inserting a fuel resistant gasket to obtain positive sealing.

For systems requiring pipes with a relatively small diameter, we

recommend using copper pipes.

For unavoidable connections we recommend using "biconic" fittings.

The annexed tables show the indicative diagrams for the different

types of systems depending on the position of the tank with respect

to the burner.

The suction pipe should run up-slope towards the burner to avoid

possible formation of gas bubbles.

Where more than one burner is installed in one boiler room, it is

essential that each burner has its own intake pipe.

Only return pipes can lead to a single manifold pipe with an adequate

cross section leading to the tank.

Never connect the return pipe directly to the intake pipe.

It is a good practice to properly heat-insulate the intake and return

pipes to prevent cooling which would otherwise affect the unit

efficiency.

Pipe diameters (to be strictly complied with are listed in the following

table.

The maximum amount of vacuum that the pump can withstand when

operating regularly and silently is 35 cm Hg. If this limit is exceeded,

normal pump operation can no longer be guaranteed.

Maximum intake and return pressure = 1 bar

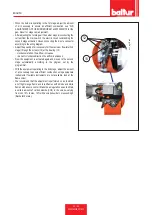

AUXILIARY PUMP

In some cases (excessive distance or differences in level) the system

must be implemented with a "loop" supply circuit with an auxiliary

pump, avoiding to connect the burner pump directly to the tank.

In this case, the auxiliary pump can be started when the burner starts

and stopped when it stops.

The electric wiring of the auxiliary pump is made by connecting the

coil (230V) which controls the pump remote control switch in parallel

to the motor-fan remote switch coil.

It is important to comply strictly with the previsions set forth here

below:

• The auxiliary pump must be installed as close as possible to the

liquid to be sucked.

• The head must be suitable for the relative plant.

• We recommend a flow rate that is at least equal to the flow rate of

the burner pump.

• Connection pipes should be sized to cope with the delivery rate of

the auxiliary pump.

• Absolutely avoid electrically connecting the auxiliary pump directly

to the contactor of the burner.

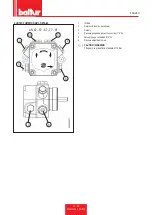

0002904150

A

B

1

Foot valve

2

Air regulation servomotor

3

2nd flame nozzle

4

1st flame nozzle

5

Normally closed safety valve

6

Pump (12 bar)

7

Normally closed valve

Содержание 56470010

Страница 2: ......

Страница 4: ...ITALIANO 2 42 0006160060_201802 ITALIANO Schemi elettrici 41 ...

Страница 43: ...ITALIANO 41 42 0006160060_201802 SCHEMI ELETTRICI ...

Страница 46: ...ENGLISH 2 42 0006160060_201802 ENGLISH Wiring diagrams 41 ...

Страница 85: ...ENGLISH 41 42 0006160060_201802 WIRING DIAGRAMS ...

Страница 87: ......