8

OVEN INTERIOR:

Clean The Racks And Rack Support Guides:

Open the doors and remove all wire racks and rack support guides. Take them to the sink and

thoroughly clean in warm water with mild detergent or soap. Use a nylon scouring pad or stiff nylon

brush.

DO NOT USE STEEL WOOL.

Clean The Stainless Steel Interior:

Baked on splatter, oil, grease or discoloration on the stainless steel inside of the oven may be removed

with stainless steel cleaner, or any other similar cleaning agent.

NEVER

use vinegar or any corrosive

cleaner. Use only cleaners approved for stainless steel.

NEVER

use cleaning solvents with a

hydrocarbon base.

NEVER

use a wire brush, steel or abrasive scouring pads, scraper, file or other steel

tools.

NOTE: ALWAYS RUB THE STAINLESS STEEL ALONG THE GRAINS.

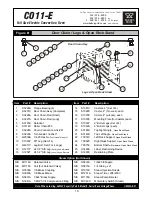

Clean The Blower Wheel:

To clean the blower wheel, remove and immerse in ammoniated water for 20 to 25 minutes. Then, scrub

it off with a small, stiff brush. The same procedure can be followed for wire racks and rack supports. To

remove the blower wheel, loosen the set screws (2) on the hub of the blower wheel and tighten the 3/8”

wheel puller bolt (supplied) in center of hub (See Fig. 1).

Clean The Porcelain Interior:

Porcelain enamel interiors are designed to be as maintenance free as possible. However, for best

results, the oven should be cleaned regularly. Enameled interiors can be easily cleaned with oven

cleaners.

KEEP CLEANING FLUIDS AWAY

FROM ELECTRICAL WIRES, LIGHT SOCKETS,

SWITCHES AND CONTROL PANEL.

OVEN EXTERIOR:

Clean The Exterior Stainless Steel:

To remove normal dirt or product residue from stainless steel, use ordinary soap and water (with or

without detergent) applied with a sponge or cloth. Dry thoroughly with a clean cloth. Never use vinegar

or corrosive cleaner. Do not use chorine based cleaners.

To remove grease and food splatter or condensed vapors that have baked on the equipment, apply

cleaners to a damp cloth or sponge and rub cleanser on the metal in the direction of the polished lines on

the metal. Rubbing cleanser as gently as possible in the direction of the polished lines will not mar the

finish of the stainless steel. To remove discoloration, use a non-abrasive cleaner.

NEVER

use a wire

brush, steel or abrasive scouring pads, scraper, file or other steel tools.

NEVER RUB WITH A

CIRCULAR MOTION

.

!

!

CAUTION:

Use mild detergent or soap solution for best results. Abrasive cleaners could scratch

the finish of your unit, marring it’s appearance and making it susceptible to dirt accumulation.

DO

NOT

use abrasive cleaners or cleaners/sanitizers containing chlorine, iodine, ammonia or bromine

chemicals as these will deteriorate the stainless steel and glass material and shorten the life of the

unit. Use nylon scouring pads.

DO NOT

use steel wool.

!

!

WARNING:

To avoid any injury, turn the power switch off at the fuse disconnect switch/circuit

breaker or unplug the unit from the power source and allow to cool completely before performing

any maintenance or cleaning.

!

WARNING:

Unit is not waterproof. To avoid electrical shock or personal injury,

DO NOT

submerge

in water.

DO NOT

operate if it has been submerged in water.

DO NOT

clean the unit with a water jet.

DO NOT

steam clean or use excessive water on the unit.

!

Always clean equipment thoroughly before first use. Clean unit daily.

3. CLEANING