22

22

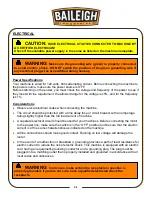

•

Improper connection of the equipment-grounding conductor can result in risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

•

Check with qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the machine is properly grounded.

•

Repair or replace damaged or worn cord immediately.

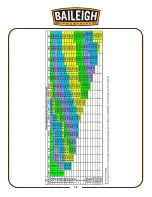

Extension Cord Safety

Extension cord should be in good condition and meet the minimum wire gauge requirements

listed below:

LENGTH

AMP RATING

25ft

50ft

100ft

1-12

16

16

14

13-16

14

12

12

17-20

12

12

10

21-30

10

10

No

WIRE GAUGE

An undersized cord decreases line voltage, causing loss of power and overheating. All cords

should use a ground wire and plug pin. Replace any damaged cords immediately.

Power cord connection:

1. Turn the main disconnect switch on the control panel to the OFF position.

2. Unwrap the power cord and route the cord away from the machine toward the power supply.

a. Route the power cord so that it will NOT become entangled in the machine in any

way.

b. Route the cord to the power supply in a way that does NOT create a trip hazard.

3. Connect the power cord to the power supply and check that the power cord has not been

damaged during installation.

4. When the machine is clear of any obstruction. The main power switch may be turn ON to test

the operation. Turn the switch OFF when the machine is not in operation.

Содержание BS-712MS

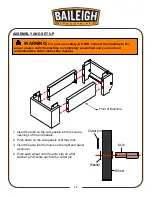

Страница 17: ...14 14 OVERALL DIMENSIONS...

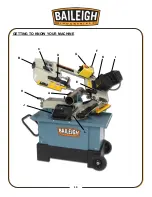

Страница 18: ...15 15 GETTING TO KNOW YOUR MACHINE A B C D E F G H I K J L...

Страница 32: ...29 29...

Страница 46: ...43 43 PARTS DIAGRAM A...

Страница 47: ...44 44 PARTS DIAGRAM B...

Страница 52: ...49 49 WIRING DIAGRAM MAGNETIC SWITCH COOLANT PUMP MOTOR 110V POWER SOURCE LIMIT SWITCH BLACK WHITE GREEN...

Страница 58: ...55 55 NOTES...

Страница 59: ...56 56 NOTES...