4 - 19

Adjustment

In

spection and

Adjustment

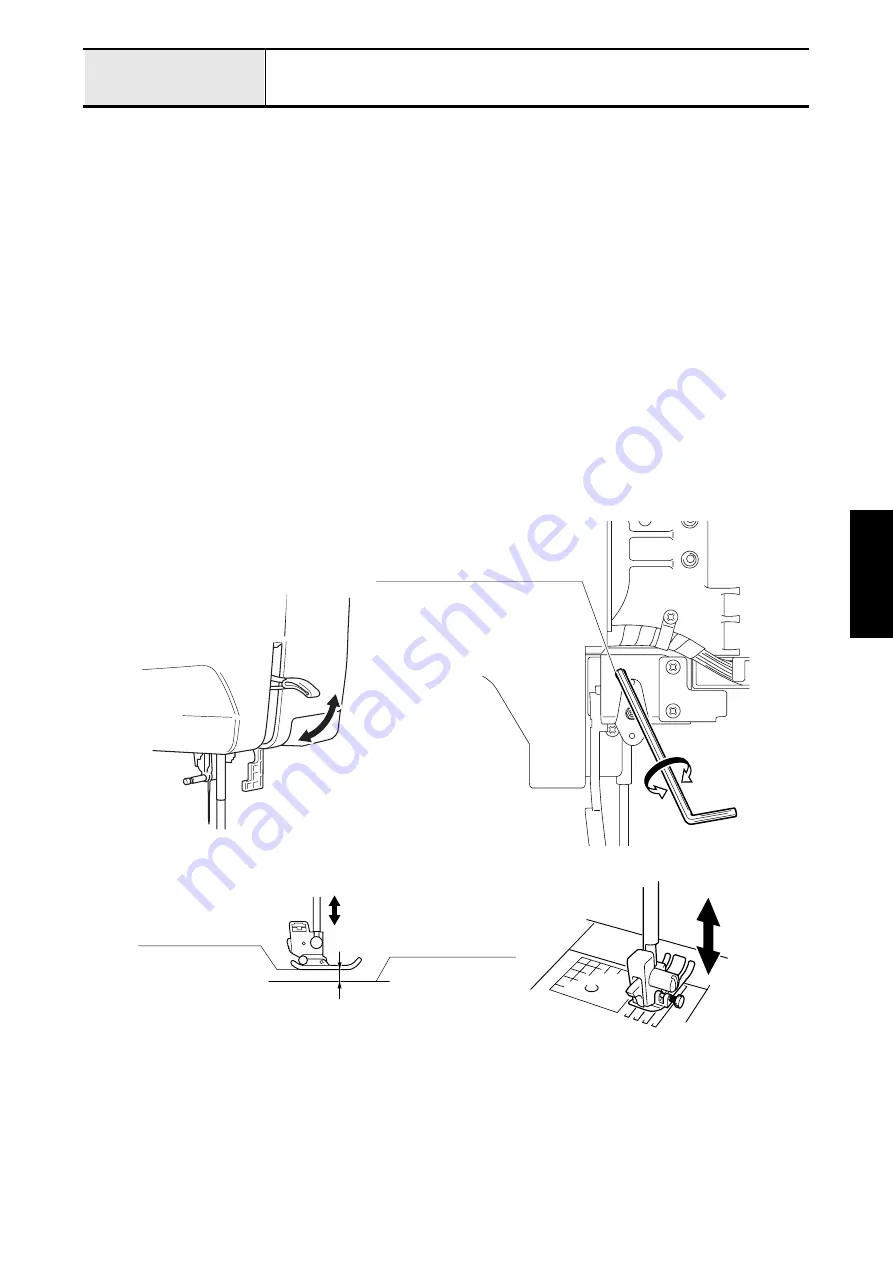

Presser bar height and parallelism

[Adjustment standard]

The clearance between the needle plate A and bottom surface of the presser foot is 7.0 to 7.5mm.

Presser foot parallel with feed dog hole.

[Adjustment procedure]

1. Remove the face plate assy..

2. Attach the J presser foot.

3. Start the test mode.

4. Raise the lift lever.

5. Turn the pulley by hand and down the feed dog lower than needle plate A.

6. Loose the socket set screw (CP, M5x10) of the needle presser bar block.

7. Adjust the needle presser bar height, clearance between the needle plate A and the bottom surface of the presser

foot is 7.0 to 7.5mm.

8. Tighten the socket set screw (CP, M5x10) of the needle presser bar block (tightening torque: 1.37 to 1.77N· m).

*Key point

•

Check presser foot parallel with feed dog hole after adjusting presser bar height.

Socket set screw (CP, M5x10)

Upper surface of

the needle plate A

Bottom surface

of the presser foot

7.0 - 7.5mm

42

Содержание Ellisimo BLSO

Страница 1: ...3...

Страница 2: ...xvi 4...

Страница 29: ...31...

Страница 35: ...Tacony Corp 10 2008 2 3 In the case that the parts separate please assemble as shown 37...

Страница 37: ...39...

Страница 55: ...4 35 Camera calibration 57...

Страница 65: ...67...