8

1-12-2 Kawana, Fujisawa

Kanagawa 251-8522 Japan

URL

: https://www.azbil.com

(11)

Specifications are subject to change without notice.

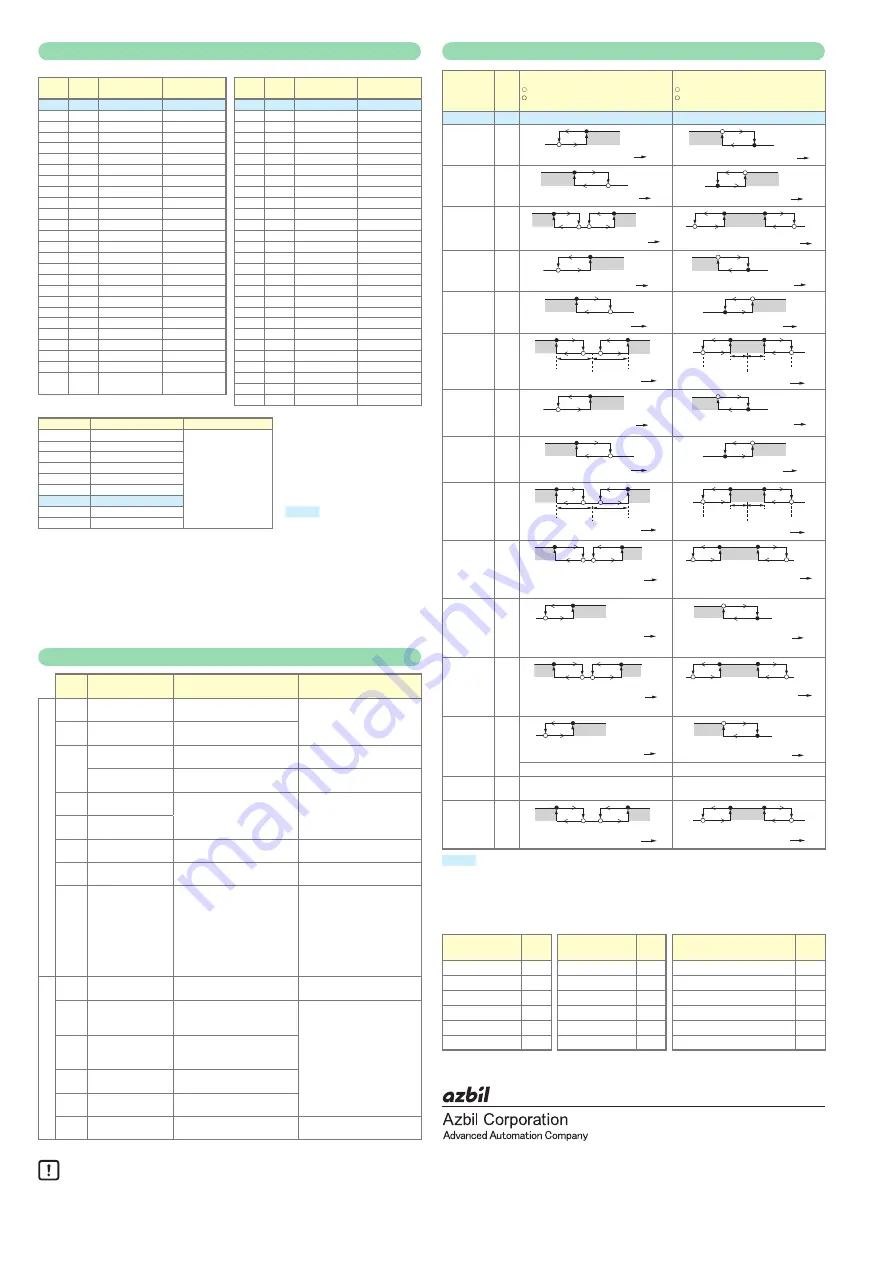

PV input range table

[Thermocouple]

[RTD]

C0

1

set value

Sensor

type

Range

(°C)

Range

(°F)

C0

1

set value

Sensor

type

Range

(°C)

Range

(°F)

1

K

-200 to +1200

-300 to +2200

41

Pt100

-200 to +500

-300 to +900

2

K

0 to 1200

0 to 2200

42

JPt100 -200 to +500

-300 to +900

3

K

0.0 to 800.0

0 to 1500

43

Pt100

-200 to +200

-300 to +400

4

K

0.0 to 600.0

0 to 1100

44

JPt100 -200 to +200

-300 to +400

5

K

0.0 to 400.0

0 to 700

45

Pt100

-100 to +300

-150 to +500

6

K

-200.0 to +400.0 -300 to +700

46

JPt100 -100 to +300

-150 to +500

7

K

-200.0 to +200.0 -300 to +400

47

Pt100

-100 to +200

-150 to +400

8

J

0 to 1200

0 to 2200

48

JPt100 -100 to +200

-150 to +400

9

J

0.0 to 800.0

0 to 1500

49

Pt100

-100 to +150

-150 to +300

10

J

0.0 to 600.0

0 to 1100

50

JPt100 -100 to +150

-150 to +300

11

J

-200.0 to +400.0 -300 to +700

51

Pt100 -50.0 to +200.0

-50 to +400

12

E

0.0 to 800.0

0 to 1500

52

JPt100 -50.0 to +200.0

-50 to +400

13

E

0.0 to 600.0

0 to 1100

53

Pt100 -50.0 to +100.0

-50 to +200

14

T

-200.0 to +400.0 -300 to +700

54

JPt100 -50.0 to +100.0

-50 to +200

15

R

0 to 1600

0 to 3000

55

Pt100 -50.0 to +100.0

-50 to +200

16

S

0 to 1600

0 to 3000

56

JPt100 -60.0 to +40.0

-60 to +100

17

B

0 to 1800

0 to 3300

57

Pt100 -60.0 to +40.0

-60 to +100

18

N

0 to 1300

0 to 2300

58

JPt100 -40.0 to +60.0

-40 to +140

19

PL II

0 to 1300

0 to 2300

59

Pt100 -40.0 to +60.0

-40 to +140

20

WRe5-26

0 to 1400

0 to 2400

60

JPt100 -10.00 to +60.00

-10 to +140

21

WRe5-26

0 to 2300

0 to 4200

61

Pt100 -10.00 to +60.00

-10 to +140

22

Ni-Ni·Mo

0 to 1300

0 to 2300

62

JPt100

0.0 to 100.0

0 to 200

23

PR40-20

0 to 1900

0 to 3400

63

Pt100

0.0 to 100.0

0 to 200

24

DIN U -200.0 to +400.0 -300 to +700

64

JPt100

0.0 to 200.0

0 to 400

25

DIN L -100.0 to +800.0 -150 to +1500

65

Pt100

0.0 to 300.0

0 to 500

26

Gold iron

chromel

0.0K to 360.0 K

0 to 360 K

66

JPt100

0.0 to 300.0

0 to 500

67

Pt100

0 to 500

0 to 900

68

JPt100

0 to 500

0 to 900

[DC voltage/DC current]

C0

1

set value

Input type

Range

81

0 to 10 mV

The scaling and deci-

mal point position can

be changed variably

in a range of –1999 to

+9999

82

-10 to +10 mV

83

0 to 100 mV

84

0 to 1 V

86

1 to 5 V

87

0 to 5 V

88

0 to 10 V

89

0 to 20 mA

Initial value

90

4 to 20 mA

*1

• The accuracy of the B thermocouple is ±4.0 %FS for a range of 260 °C or less, ±0.4 %FS for 260

to 800 °C and ±0.2 %FS for 800 to 1800 °C. The PV values under 20 °C are not shown.

• The accuracy of the No.15 (sensor type R) or No.16 (sensor type S) is ±0.2 %FS for a range of 100

°C or less, and ±0.15 %FS for 100 to 1600 °C.

• The accuracy of the No.23 (sensor type PR40-20) is ±2.5 %FS for 0 to 300 °C, and ±1.5 %FS for

300 to 800 °C, ±0.5 %FS for 800 to 1900 °C.

• The accuracy of the No.26 (sensor type gold iron chromel) is ±1.5 K.

• The accuracy of the No. 55 to 62 and 81 are ±0.15 %FS ±1digit for each ranges.

*2 The indicated low limit for a B thermocouple is 20°C. However, if ROM version 1 of the instrument

information bank (

I

d02

) is prior to 2.04, the value is -180°C.

List of alarm codes

Alarm

code

Failure name

Cause

Corrective action

Input failur

e

AL0

1

PV input failure

(Over-range)

Sensor burnout, incorrect wiring,

incorrect PV input type setting

Check the wiring.

Set the PV input type

again.

AL02

PV input failure

(Under-range)

Sensor burnout, incorrect wiring,

incorrect PV input type setting

AL03

CJ failure

Terminal temperature is

faulty (thermocouple).

Check the ambient

temperature.

PV input failure

(RTD)

Sensor burnout, incorrect

wiring

Check the wiring.

AL05

RSP input failure *

1

(over range)

Sensor line break, incorrect

wiring, incorrect RSP range

setting

Checking wiring or reset

RSP range code.

AL06

RSP input failure *

1

(under range)

AL07

MFB input failure Motor line break, incorrect

wiring

Checking wiring or confirm

the MFB input.

AL

10

Motor adjust-

ment failure

Motor line break, incorrect wir-

ing, motor power supply failure.

Checking wiring, confirm the

motor power supply, reset.

AL

1

1

CT input failure

(Over-range)

(CT input 1 or 2,

or both)

A current exceeding the

upper limit of the display

range was measured. The

number of CT turns or the

number of CT power wire

loops is incorrectly set, or

wiring is incorrect.

•

Use a CT with the cor-

rect number of turns for

the display range.

•

Reset the number of CT

turns.

•

Reset the number of CT

power wire loops.

•

Check the wiring.

Unit failur

e

AL70

A/D conversion

failure

A/D converter is faulty.

Replace the unit.

AL95

Parameter failure Power is shut-down while

the data is being set, or

data is corrupted by noise.

•

Restart the unit.

•

Set the data again (set

data for

AL95

/

97

and

adjustment data for

AL96

/

98

.

•

Replace the unit.

AL96

Adjustment data

failure

Power is shut-down while

the data is being set, or

data is corrupted by noise.

AL97

Parameter failure

(RAM area)

Data is corrupted by noise.

AL98

Adjustment data

failure (RAM area)

Data is corrupted by noise.

AL99

ROM failure

ROM (memory) is faulty.

•

Reset the unit.

•

Replace the unit.

*1 Displays in RSP mode

Handling Precautions

•

If ROM version 1 (

i

d02

) of the instrument information bank

is 2.04 or earlier, CT input failure (

AL

1

1

) is not displayed.

Event type

Operation

type

Set

value

Direct action

: shows that the ON/OFF is changed at this value.

: shows that the ON/OFF is changed at a point

that "1U" is added to this value.

Reverse action

: shows that the ON/OFF is changed at this value.

: shows that the ON/OFF is changed at a point

that "1U" is added to this value.

No event

0

Always OFF

Always OFF

PV high

limit

1

ON

HYS

Main setting

PV

ON

HYS

Main setting

PV

PV low limit

2

Main setting

PV

ON

HYS

Main setting

PV

ON

HYS

PV high/low

limit

3

Main setting *1 Sub-setting *1

PV

ON HYS

ON

HYS

Main setting *1 Sub-setting *1

PV

ON

HYS

HYS

Deviation

high limit

4

ON

HYS

SP + Main setting

PV

ON

HYS

SP + Main setting

PV

Deviation

low limit

5

SP + Main setting

PV

ON

HYS

SP + Main setting

PV

ON

HYS

Deviation

high/low

limit

6

Main setting Sub-setting

SP

PV

ON

HYS

ON

HYS

ON

HYS

HYS

Main setting Sub-setting

SP

PV

Deviation

high limit

(Final SP

reference)

7

ON

HYS

SP + Main setting

PV

ON

HYS

SP + Main setting

PV

Deviation

low limit

(Final SP

reference)

8

SP + Main setting

PV

ON

HYS

SP + Main setting

PV

ON

HYS

Deviation

high/

low limit

(Final SP

reference)

9

Main setting Sub-setting

SP

PV

ON

HYS

ON

HYS

ON

HYS

HYS

Main setting Sub-setting

SP

PV

Heater 1

burnout/

Over-current

16

CT1 at output ON

Main setting *1

Sub-setting *1

ON HYS

ON

HYS

ON

HYS

HYS

Main setting *1

Sub-setting *1

CT1 at output ON

OFF before measuring the CT1 current value OFF before measuring CT1 current value

Heater 1

short-circuit

17

ON

HYS

Main setting

CT1 at output OFF

ON

HYS

Main setting

CT1 at output OFF

OFF before measuring CT1 current value OFF before measuring CT1 current value

Heater 2

burnout/

Over-current

18

CT2 at output ON

Main setitng *1 Sub-setting *1

ON HYS

ON

HYS

ON

HYS

HYS

Main setting *1

Sub-setting *1

CT2 at output ON

OFF before measuring CT2 current value OFF before measuirng CT2 current value

Heater 2

short-circuit

19

ON

HYS

Main setting

CT2 at output OFF

ON

HYS

Main setting

CT2 at output OFF

OFF before measuring CT2 current value OFF before measuring CT2 current value

Alarm

(status)

23 ON if alarm occurs (alarm code AL01 to 99).

OFF in other cases.

OFF if alarm occurs (alarm code AL01 to 99).

ON in other cases.

High and

low limits of

MFB value*

2

33

Main setting*1 Sub-setting*1

MFB

ON

HYS

ON

HYS

ON

HYS

HYS

Main setting*1

Sub-setting*1

MFB

: initial value

*1 If the main setting is greater than the sub-setting, operations are performed with the

main setting and sub-setting automatically swapped.

*2 Motor feedback

Event types other than the above:

Operation type

Set

value

Operation type

Set

value

Operation type

Set

value

SP high limit

10

Loop diagnosis 1

20

During AT (status)

27

SP low limit

11

Loop diagnosis 2

21

During SP ramp

28

SP high/low limit

12

Loop diagnosis 3

22

Control action (status)

29

MV high limit

13

READY (status)

24

ST setting standby (status)

30

MV low limit

14

MANUAL (status)

25

Estimated position contorol (status)

31

MV high/low limit

15

RSP (status)

26

Timer (status)

32

1st edition: Dec. 2007 (W)

3rd edition: May 2019 (B)

© 2007–2019 Azbil Corporation. All Rights Reserved.