Measuring the dynamic pressure

The system vacuum reached in free suction is measured. The measurement

duration is approx. 1 s. To evaluate a valid dynamic pressure value therefore, after

the start of suction the system should suction freely for at least 1s, i.e. the suction

point may not be occupied by a component yet.

Measurement values below 5 mbar or above the threshold value H1 are not

considered valid dynamic pressure measurements and discarded. The result of the

last valid measurement is sustained.

Measurement values above the threshold value (H2-h2) and at the same time below

the threshold value H1 result in a Condition Monitoring event.

Quality evaluation

To evaluate the entire gripping system the ejector calculates a quality evaluation

based on the measured system leakage.

The higher the leak rate in the system the lower the quality of the gripping system.

Vice versa, a low leak rate results in high quality evaluation.

Calculating performance

Similar to the quality evaluation, the performance calculation is used to evaluate the

system state. Based on the determined dynamic pressure an assessment of the

performance of the gripping system can be made.

Optimally designed gripping systems result in low dynamic pressure and thus high

performance, vice versa badly designed systems exhibit low performance values.

Dynamic pressure results that are higher than the threshold value of (H2-h2) always

result in a performance evaluation of 0%. A performance evaluation of 0% is also

issued for a dynamic pressure value of 0 mbar (which is an indication for an invalid

measurement).

Diagnostic buffer

The Condition Monitoring warnings and general error messages of the device are

stored in a diagnostic buffer.

This storage contains the last 38 events starting with the latest and it can be read

out via an IO-Link parameter. The currently valid counter reading of the suction cycle

counter cc1 is included with each event, to allow subsequent chronological

association of the events with other processes within the system. For the precise

data presentation of the diagnostic buffer see the respective device description file

(IODD).

Recording of these events is also active in the SIO mode and the stored contents are

retained after a power failure. The storage is manually deleted with the IO-Link

system command “Clear diagnostic buffer” or by resetting the device to the factory

settings.

EPC data buffer

To allow long-term monitoring and trend analysis of the most important key figures

of a handling process, the ejector contains a ten-step data buffer. It is available for

storage of the measurement values of the evacuation time t

1

, the leak rate and the

dynamic pressure (vacuum with free suctioning) determined in the current suction

cycle.

The values are always automatically stored in conjunction with the implementation

of the above described Autoset function in Condition Monitoring. The currently valid

counter reading of the suction cycle counter cc1/ct1 is included with each data set,

to allow their subsequent chronological association with other processes within the

system. The contents of the EPC diagnostic buffer can be read out via an IO-Link

parameter whose precise data presentation can be found in the respective device

description file (IODD). The stored contents are retained after a power failure.

EPC values in the process data

For the quick and convenient recording of the events of the functions Condition

Monitoring, Energy Monitoring and Predictive Maintenance, they are also made

available via the process input data of the device. For this purpose, the top 3 bytes of

the process input data are designed as a multi-functional data section, consisting of

an 8-bit value (“EPC value 1”) and a 16-bit value (“EPC value 2”).

The contents of this data currently provided by the ejector can be switched via the

process output data with the 2 bits “EPC Select”. The four possible assignments of

this data are shown in the following table:

PDO

PDI

EPC

select:

EPC value 1 (8-bit)

EPC value 2 (16-bit)

EPC

select

acknowledge

00

Current input pressure

(unit 0.1 bar)

Current vacuum value

(unit 1 mbar)

0

01

Condition Monitoring

Evacuation time t

1

(unit 1 ms)

1

10

Leak rate

(unit 1 mbar/s)

Last measured dynamic

pressure

(unit 1 mbar)

1

11

Supply voltage

(unit 0.1 V)

Air consumption

(unit 0.1 NL)

1

AVENTICS

| ECD-IV/ECD-LV | R412026283–BAL–001–AA | English

19

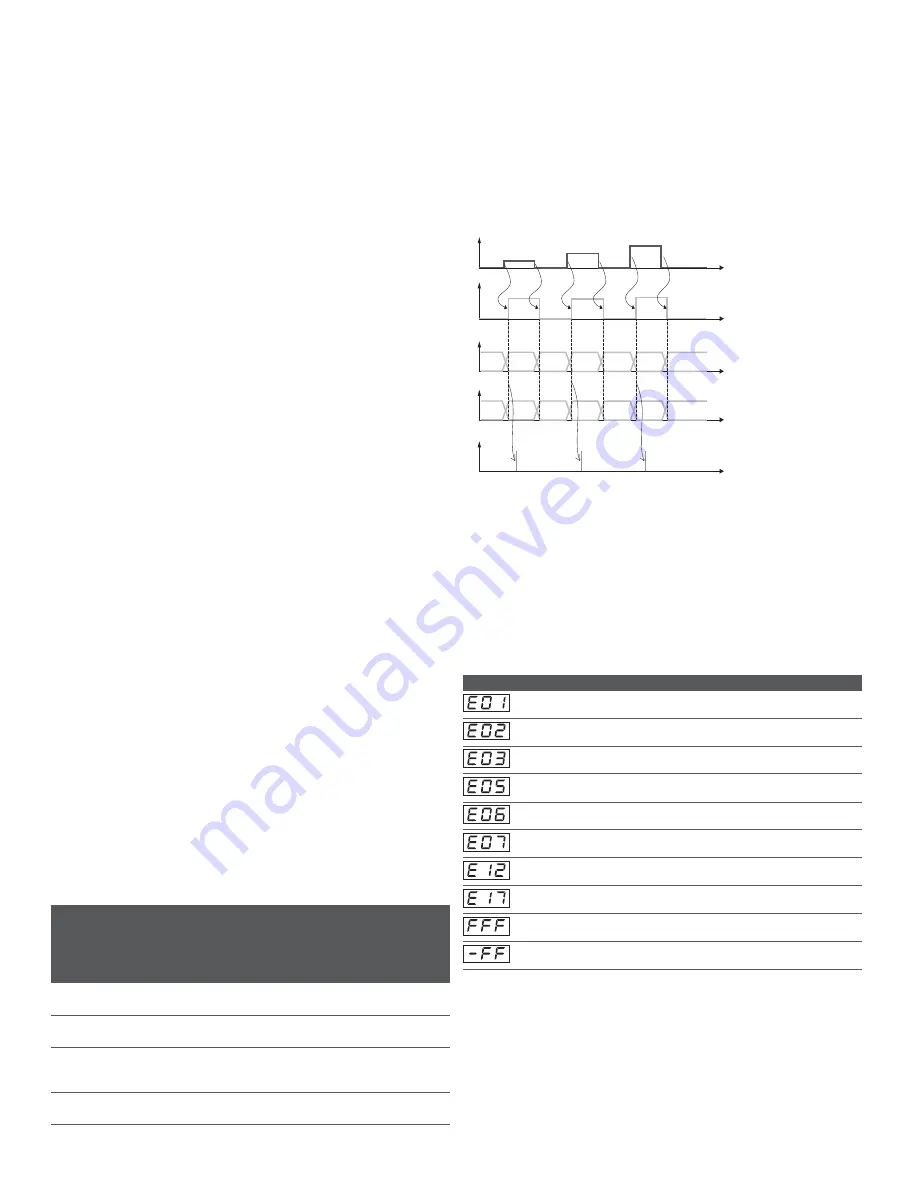

Depending on the design of the automation system, the switching takes place with a

certain delay. The bit EPC Select Acknowledge is available in the process input data

to allow the efficient reading in of the various value pairs by a control program.

The bit always accepts the values shown in the table. The process described in the

following diagram is recommended for reading out all EPC values:

Always start with EPC Select = 00 and then select the next desired value pair,

e.g. EPC Select = 01. Now wait for the EPC Select Acknowledge bit to switch from

0 to 1. This ensures that the transferred values correspond to the selection and can

be adopted by the control.

Now switch back to EPC Select = 00 and wait for the EPC Select Acknowledge bit to

be reset to 0 by the ejector. Now you can carry out the process for the next value pair,

e.g. EPC Select = 10 in the same way, and so on.

7

Troubleshooting

Error

The ejector's error messages are shown on the display.

EPC select:

[PDOut 0.5...0.4]

EPC select acknowledge

[PDIn 0.3]

EPC value 1

[PDIn 1]

EPC value 2

PDIn 3...2]

Control adopts valid EPC

values

1 = Pressure

2 = CM

3 = Leakage

4 = Voltage

5 = Vacuum

6 = Evacuation time

7 = Dynamic pressure

8 = Air consumption

Symbol

Error code

Electronics error - EEPROM

Electronics error – Internal communication

Zero-point adjustment for the vacuum sensor outside of

±

3% FS

Actuator supply voltage too low

(display alternating with current vacuum value)

Manual operation not possible during the “Blow-off” operating state

Supply voltage too low

Short circuit in output 2/OUT signal output

Supply voltage too high

Vacuum created exceeds the measurement range

Overpressure in the vacuum circuit

00

00

00

11

10

01

1

1

1

1

4

5

6

7

8

5

5

5

3

2

Содержание ECD-IV

Страница 30: ......