41

Installation Manual

2. Danger zone! sticker

3. Disassembling

STOP

ASL508

4. Inspection before initial use

A certified technician must:

a) I nspect the lift as specified in section 13.1 or

13.2 of the User’s Manual.

b) Carry out a test run with the maximum rated

load.

c) Overload test: The test load depends on the lift

motor. Load the cabin as follows: Motor M508:

load kg 320 (125% of lifting ca weight

of power cable). When an attempt is made to

start the lift, the platform should stop, and the

buzzer in the connection cabinet should sound.

- If not, see “Regulation of overload limiter”

Appendix.

d) The guide, drive and safety wire ropes as well

as the top and bottom wire rope fastenings

must be tested at full length as part of the initial

test run.

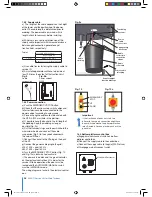

e) Testing of the

fall arrest device:

Important!

Before testing, the tightening spring beneath

the access platform must be removed.

Remember to secure it again after testing!

DANGER!

If the fall arrest device is engaged, it must not

be possible to pull the safety wire upwards!

1) Engage the fall arrest device by pressing the

stop button – the handle should jump to the

“ON” position (Fig. 16).

Should it nevertheless be possible to pull the

safety wire rope upwards, the fall arrest device

must be replaced and sent to the supplier for

testing.

2) Reopen the fall arrest device by pressing down

on the lever. On top of the lift, pull up the safety

wire rope with a quick jerk – the fall arrest

device should now engage automatically; if it

does not, replace it and return to the supplier for

testing.

f) If guide wire ropes are mounted using the tripod,

tighten the tripod wire rope locking device.

The results from this test must be recorded

in writing and saved for later reference

“Inspection Checklist” Appendix.

Fig. 15

Safety wire

UNLOCK

LOCK

Window

AT00016288 Shark L AECO EN update.indd 41

11/14/2018 4:02:59 PM