35

!

Installation Manual

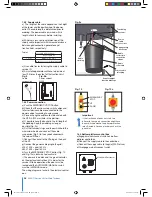

1. Mount the preassembled tensioner underneath the

bottom platform floor.

2. Place the threaded shaft in the toppest position

(see Fig. 8b).

3. Feed the guiding wire rope by hand through the

threaded shaft.

4. Stretch the wire rope pulling downwards.

5. Install the wire rope grips.

6. While locking the threaded shaft with a spanner in

the shaft indentations, turn the tensioning nut until

dial indicates 2KN – 4KN (see Fig. 8c).

7. Fasten the locking nut.

8. Mount the second tensioner.

1.3.4 Tensioning the guide wire ropes Ø0.47 in (12 mm)

Tighten the wire ropes by hand and mark with a water-

resistant marker. Measure the distance to the floor.

• For 197 ft (60 m) long wire rope, stretch the wire rope

2.36 in (60 mm).

• For 262.46 ft (80 m) long wire rope, stretch the wire

rope 3.15 in (80 mm).

• For 328.08 ft (100 m) long wire rope, stretch the wire

rope 3.94 in (100 mm).

For each additional 32.8 ft (10 m), stretch the wire rope

by a further 0.39 in (10 mm).

After some time it may be necessary to stretch 196,85 ft

(60 m) wire rope by another 1.19 in (5 mm) and longer

wire rope by a further 0.27-0.39 in (7-10 mm) (all wire

ropes stretches after some time).

ATTENTION!

This will tighten the wires to approximately 2000-

4000 N.

1.3.3 Method 3: Graduated tensioner

Mount the guiding wire ropes as shown in following

figures and as explained in procedure below.

1.4 Electrical connections

1.4.1 Power supply

DANGER!

The electrical connection of the traction hoist must

be made in accordance with EN 60204-1.

The power supply must be protected by a fuse

and an earth leak circuit breaker (30mA).

Disconnect the main power supply before handling

power units.

Verify that the rated grid and motor voltages are

identical. The three-phase motor is normally

supplied in a star connection configuration:

Necessary equipment to comply with EN60204-1

can be supplied by Avanti as an option.

400V 3 gnd. Y I = 4.9A 1.8 kW 66 ft/min 21m/min

480V 3 gnd. Y I = 4.1A 1.8 kW 66 ft/min 21m/min

Control voltage: 230 V / 240 V

Locking Nut

Tensioning Nut

Wire rope grips

Spring tensioner

Indicating dial

Indicating dial

Guiding wire rope

Bottom platform floor

Base tube

Graduated tube

Indentations

Threaded shaft

Fig. 8c Installation of tensioner - Phase 2

Fig. 8b Installation of tensioner - Phase 1

AT00016288 Shark L AECO EN update.indd 35

11/14/2018 4:02:52 PM