24

STOP

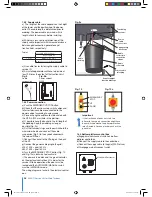

AVANTI Service Lift for Wind Turbines

Breakdown

Cause

Solution

The service lift

will

neither go

up nor down!

DANGER!

Attempting to use the lift will jeopardize work safety

A1 The fixed EMERGENCY STOP

button is activated.

Turn this button clockwise until it moves

out to deactivate it.

A2 Wire rope loop

on traction hoist.

Damaged or defective wire rope or

wire rope outlet causes problems.

Stop work immediately!

Ask the supplier or manufacturer for help.

A3 The fall arrest device is

holding the service lift on the

safety wire rope.

a) Traction wire rope breakage

b) Hoist failure

a) + b) Evacuate the service lift and

follow the directions in section 8

A4 The service lift is stuck on an

obstacle.

Carefully remove the obstacle.

Test the operational safety of affected

building sections. Inform the supervisor.

A5 Power failure

a) The control is not set to ON.

b) Grid voltage interrupted

c) Supply between grid connection

and control interrupted

a) Turn EMERGENCY STOP switch

clockwise until it is released

b) Find the cause and wait for the power

to return

c) Test and if necessary repair the supply

cable, guide wires, fuses, and/or

wiring from the control box

A6 Limit stop switch functions

a) EMERGENCY limit stop switch is

pressed.

b) Door limit stop switch is

blocked

or is defective.

a) Manually take the lift down until the

limit stop switch is released.

b) Close the doors and test the limit stop

switch.

A7 Protection switch on

overheating

a) A phase is missing

b) Motor is not cooling

c) Voltage too high/low

a) Test/repair fuses, supply and connec-

tion.

b) Clean the hood.

c) Measure voltage and power consump-

tion on the loaded motor. If voltage

does not obey the specifications, use

cable with increased dimensions.

A8 Brake does not open (no click on on/off)

a) Supply, braking coil or

rectifier defective.

b) Braking rotor closes.

a) Have an electrician test, repair/replace

the supply, braking coil and rectifier.

b) Return the traction hoist to the

manufacturer for repair.

10. Troubleshooting

1.

All tests and repairs to the electronic compo-

nents should be performed by

certified

technicians only!

The power chart is placed

in the traction hoist’s power cabinet.

2.

Repairs to the traction hoist, the fall arrest

device and to the system’s supporting compo-

nents should be performed by

certified

technicians only!

DANGER!

Unplug the power

supply before

opening the power

cabinet.

AT00016288 Shark L AECO EN update.indd 24

11/14/2018 4:02:46 PM