Revised 8/14/02 • U551

7

© 2002 Automated Logic Corporation

Reference Guide

or the

Eikon Microblock

Reference Guide

for more information

about the LogiStat microblock.

6. Disconnect the LogiStat Adaptor cable

from the LogiStat’s LogiPort when

finished to allow the U551 to read inputs

from the LogiStat.

Input Wiring

The U551 inputs support the types of signals

listed below. The LogiStat, LogiStat Plus, and

LogiStat Pro sensors are supported through

the module’s LogiStat port. The U551

provides five inputs: two on the LogiStat port

and three analog inputs. Refer to Table 1 for

information about wire length, gauge, and

shielding. Make sure the U551’s power is off

before wiring any inputs or outputs.

NOTE

If you are using both flow sensors on

a UDF, disable the U551’s IN-3 input by

removing its jumper. Disabling the IN-3

allows a second flow sensor input (Flow #2)

on the UDF to be read through the flow

sensor on the U551.

• Thermistor: Precon type 2 (10kohm at

77°F). Input voltages should range

between 0.489V and 3.825V for

thermistors.

• 0 to 5VDC: When using 0 to 5VDC

signals, remove the pull up jumpers of

the U551. The pull up jumpers are

located behind the input port. You must

remove the cover to access the pull up

jumpers. The output impedance of a 0

to 5VDC source must not exceed

10kohms. The input impedance of the

U551 is approximately 1Mohm.

• Dry Contact: A 5VDC wetting voltage is

used to detect contact position. This

results in a 0.5mA maximum sense

current when the contacts are closed.

No pulse accumulation inputs are allowed in

U551 FBs, except for the override button on

the LogiStat.

Using the LogiStat

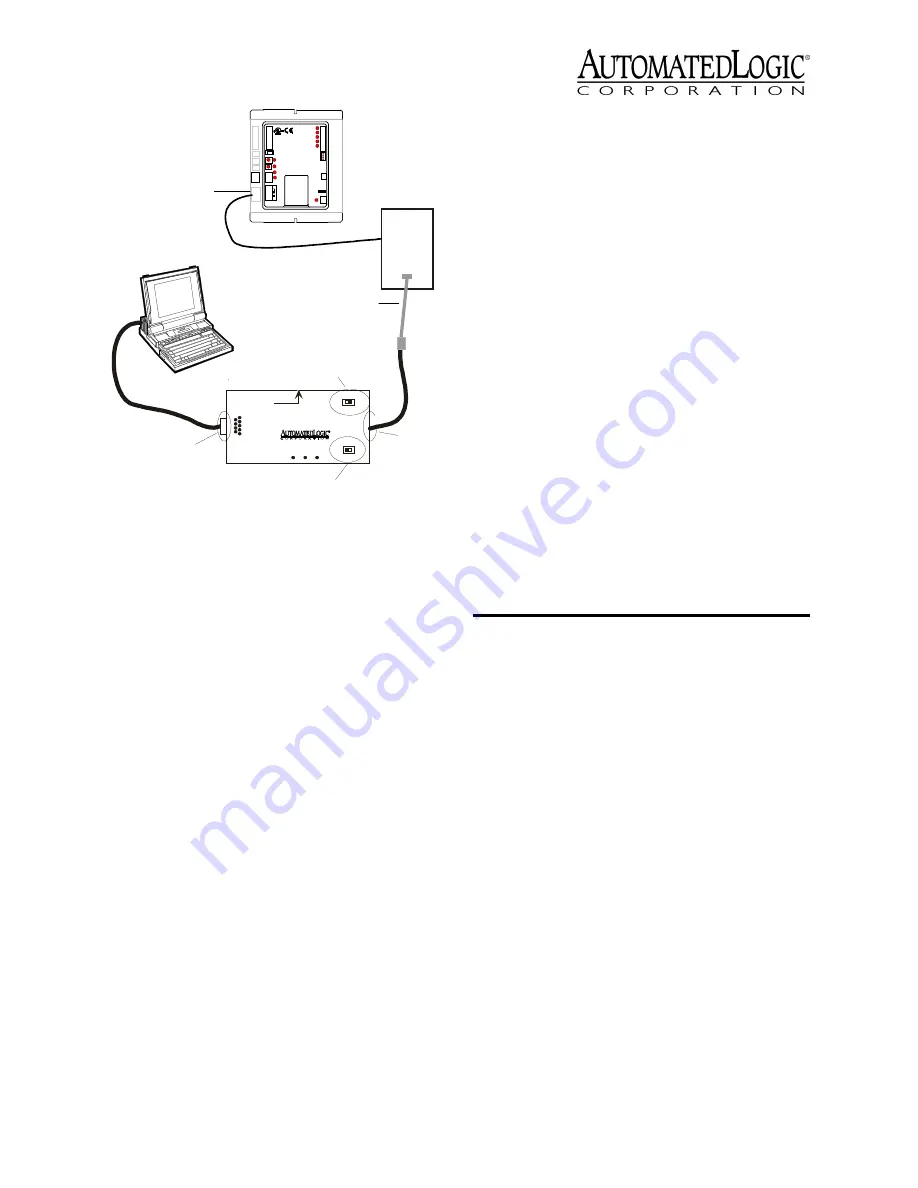

Use Figure 7 and Figure 8 on page 8 to wire a

LogiStat, LogiStat Plus, or LogiStat Pro to the

U551.

Automated Logic Corporation recommends a

specific wire to connect the U551 to the

LogiStat. This 22AWG solid copper wire is

available from Magnum Cable Corporation,

product number A3LOGISTAT.

Figure 6. Using the LogiPort

Gnd

24 Va c

G n d

T e m p

S w

LS 5v

U n e t +

U n e t -

U - c o m

O n

O f f

BACnet

U551

9

Rx

6 1

2- Tx out

3- Rx in

5- Gnd

1,6,8- +10Vor floating

Tx

+5V

A P T

5

Exec. 4relay

Isolate Network

ModeSelect

TTL

485

ACCESS

PORT

Supplemental

Power

+5V dc

LogiStat

Port

LogiStat Adaptor Cable

Access

Port

Mode Select

Switch

EIA-232

Port

Exec 4 Relay

Switch

LogiStat

Table 1. Input Wiring Restrictions

Input

Maximum

Length

Minimum

Gauge

Shielding

Universal

50 feet

15 meters

24AWG

shielded and

grounded to

module’s “-”

or Gnd

terminal

LogiStat

Sensors

100 feet

30 meters

22AWG

unshielded