6

1)

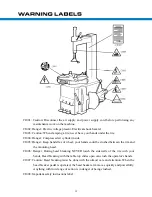

BEFORE PERFORMING ANY SERVICES OR MAINTENANCE; ALWAYS

DISCONNECT THE TIRE CHANGER FROM ITS AIR SUPPLY SOURCE. DEPRESS

AND RELEASE AIR ACTUATED PEDALS SEVERAL TIMES TO EVACUATE ALL

COMPRESSED AIR FROM THE MACHINE AND DISCONNECT THE POWER CORD

FROM ITS ELECTRICAL SUPPLY SOURCE. (Don’t forget about the bead breaker)

2)

TIRE CHANGER OPERATES ON CLEAN, DRY, COMPRESSED AIR REGULATED TO

125 PSI. DO NOT EXCEED 150 PSI INLET PRESSURE TO THE REGULATOR OR

MACHINE DAMAGE COULD OCCUR. AIR REGULATOR ON THE SIDE OF

MACHINE SHOULD BE SET NO HIGHER THEN 125 PSI.

3)

THE AUTOMATIC OILER PROVIDES LUBRICATION TO THE MOVING PARTS OF

THE TIRE CHANGER. IF THE AUTOMATIC OILER IS NOT USED, ADD TWO DROPS

OF AIR TOOL OIL (DAILY) TO THE AIR SUPPLY LINE. THIS WILL HELP TO

PROVIDE SUFFICIENT LUBRICATION TO THE MOVING PARTS AND SEALS.

4)

ALWAYS INFLATE THE TIRE TO THE AIR PRESSURE RECOMMENDED BY THE

TIRE MANUFACTURER. NEVER OVER INFLATE THE TIRE.

5)

MAKE SURE THAT THE TIRE AND RIM SIZE ARE A PERFECT MATCH. SEVERE

PERSONAL INJURY WILL RESULT IF THE TIRE SIZE AND RIM SIZE ARE

DIFFERENT AND THE INFLATED TIRE “BLOWS OFF” THE RIM WHEN INFLATED.

ALWAYS DISPOSE OF OLD TIRES ACCORDING TO LOCAL AND NATIONAL TIRE

DISPOSAL REGULATIONS.

6)

TO AVOID PERSONAL INJURY AND/OR TIRE MACHINE DAMAGE, ALWAYS MAKE

SURE THE RIM IS FIRMLY SECURED ON THE TIRE CHANGER (with the clamping

jaws) BEFORE REMOVING, INSTALLING, OR INFLATING A TIRE.

7)

NEVER PLACE YOUR HANDS BETWEEN THE WHEEL RIM AND THE JAWS

DURING THE LOCKING/CLAMPING STAGE. THE AIR OPERATED CLAMPING

JAWS EXERT AN EXTREME AMOUNT OF PRESSURE AND SEVERE PERSONAL

INJURY MAY OCCUR IF ANY EXTREMITIES ARE “CAUGHT” IN THE JAWS.

Содержание TC589X

Страница 1: ...1 ...

Страница 27: ...27 ...

Страница 29: ...29 ...

Страница 30: ...30 ...

Страница 31: ...31 ...

Страница 32: ...32 ...

Страница 33: ...33 ...

Страница 34: ...34 ...

Страница 35: ...35 ...

Страница 36: ...36 ...

Страница 40: ...40 ...

Страница 41: ...41 ...

Страница 42: ...42 ...

Страница 43: ...43 ...

Страница 44: ...44 ...