24

IP VERSION

If the tire changer is equipped with the IP set, there is a tire inflator pedal on the left side of the

machine. When the pedal is depressed half way, the inflator will operate. While the pedal is

depressed, the air gauge on the inflator box will indicate the pressure of the air flowing through

the hose into the tire. When the pedal is not depressed, this gauge will display the air pressure

inside the tire (when the inflation hose is attached to the valve stem).

The accuracy of the air gauge is not absolute. It is provided as a reference only. The air pressure

of the tire should be rechecked with a digital hand held gauge to assure proper inflation pressure

before the tire and wheel are installed on a vehicle. NEVER INFLATE A TIRE ABOVE THE

TIRE MANUFACTURER’S SPECIFICATIONS.

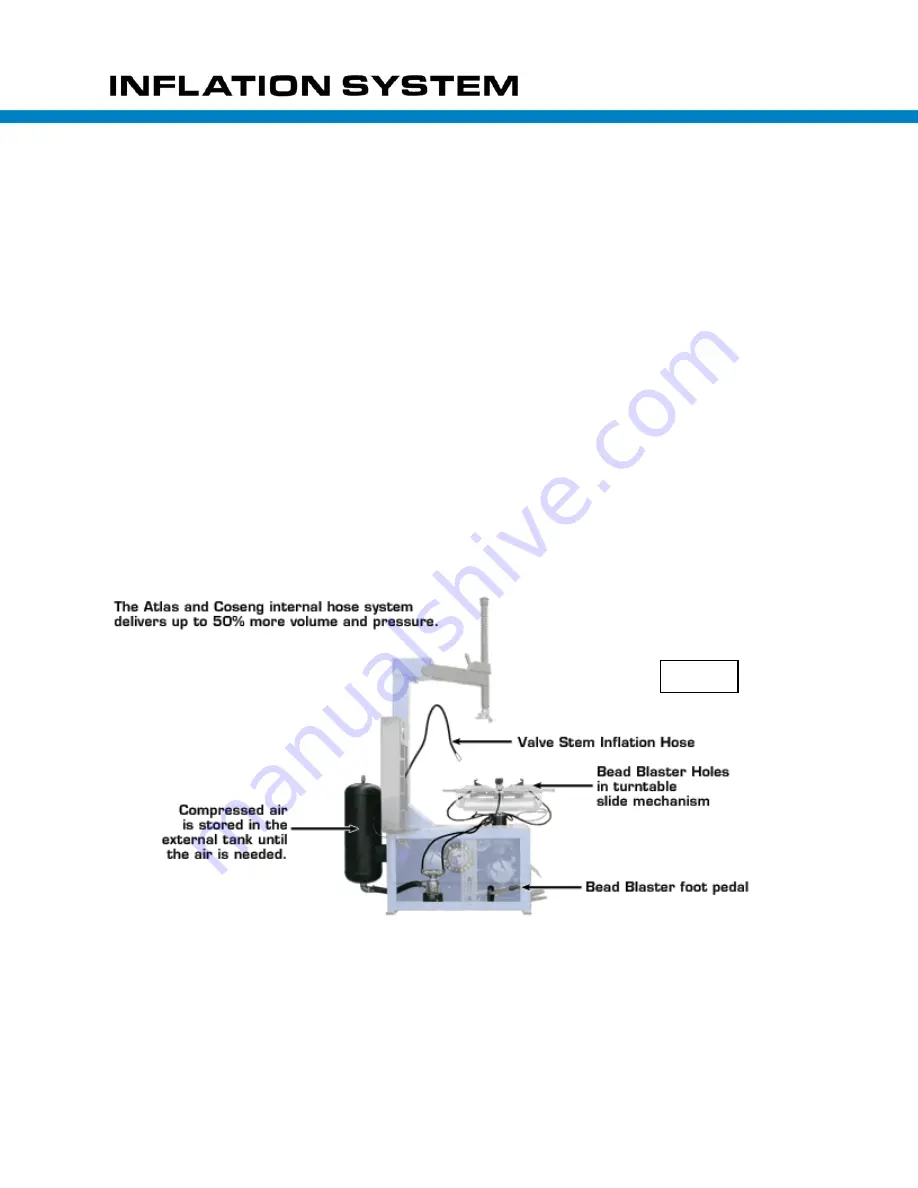

A tire changer’s bead blaster system delivers a large volume of highly pressured air into the

cavity of a tubeless tire to help “seat the beads” of the tire to the wheel assembly. Many tubeless

tires have extremely stiff sidewalls and the beads of these tires will not seat properly by just

pumping air through the valve stem. (Even with the valve core removed)

The “bead blaster” system of the modern tire changer takes the place of the “spray ether and a

match technique” used by tire people with no regard for their own safety. See movie clip below.

All tire changer bead blaster systems operate in the same basic way, but the Atlas and Coseng tire

changers utilize a special internal hose and oversized tank system that delivers up to 50% more

volume and pressure than most competitors’ bead blaster systems.

Compressed air is stored in the external tank until that air is needed for the bead blaster. The

delivery of the air is controlled by a foot pedal on the machine. When the pedal is partially

depressed, the air flows into the tire through the hose attached to the valve stem. When the pedal

is fully depressed, a large volume of compressed air is “blasted” into the cavity of the tire

through holes located on the turntable slide mechanism. (Just behind the clamping jaws). This

blast of air occurs while additional air is being introduced through the valve stem inflation hose.

The combination of the valve stem air supply and the "bead blasted" air is usually enough to seat

the beads of the most stubborn tires.

Fig. IP1

Содержание TC589X

Страница 1: ...1 ...

Страница 27: ...27 ...

Страница 29: ...29 ...

Страница 30: ...30 ...

Страница 31: ...31 ...

Страница 32: ...32 ...

Страница 33: ...33 ...

Страница 34: ...34 ...

Страница 35: ...35 ...

Страница 36: ...36 ...

Страница 40: ...40 ...

Страница 41: ...41 ...

Страница 42: ...42 ...

Страница 43: ...43 ...

Страница 44: ...44 ...