Manual, Control Module, PROFINET, DL12

Document #9620-20-C-DL12-06

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 •

C-22

8. Connect the 5‑pin power cable and PROFINET cable connectors to the module.

9. Remove the 5 mm set screw from the FE ground terminal using a 3 mm hex key.

10. Connect the ground to the FE grounding terminal using a M5 customer supplied fastener.

11. Set the Tool‑ID. Refer to

Section 3.8—Setting the Tool‑ID.

12. After the procedure is complete, resume normal operation.

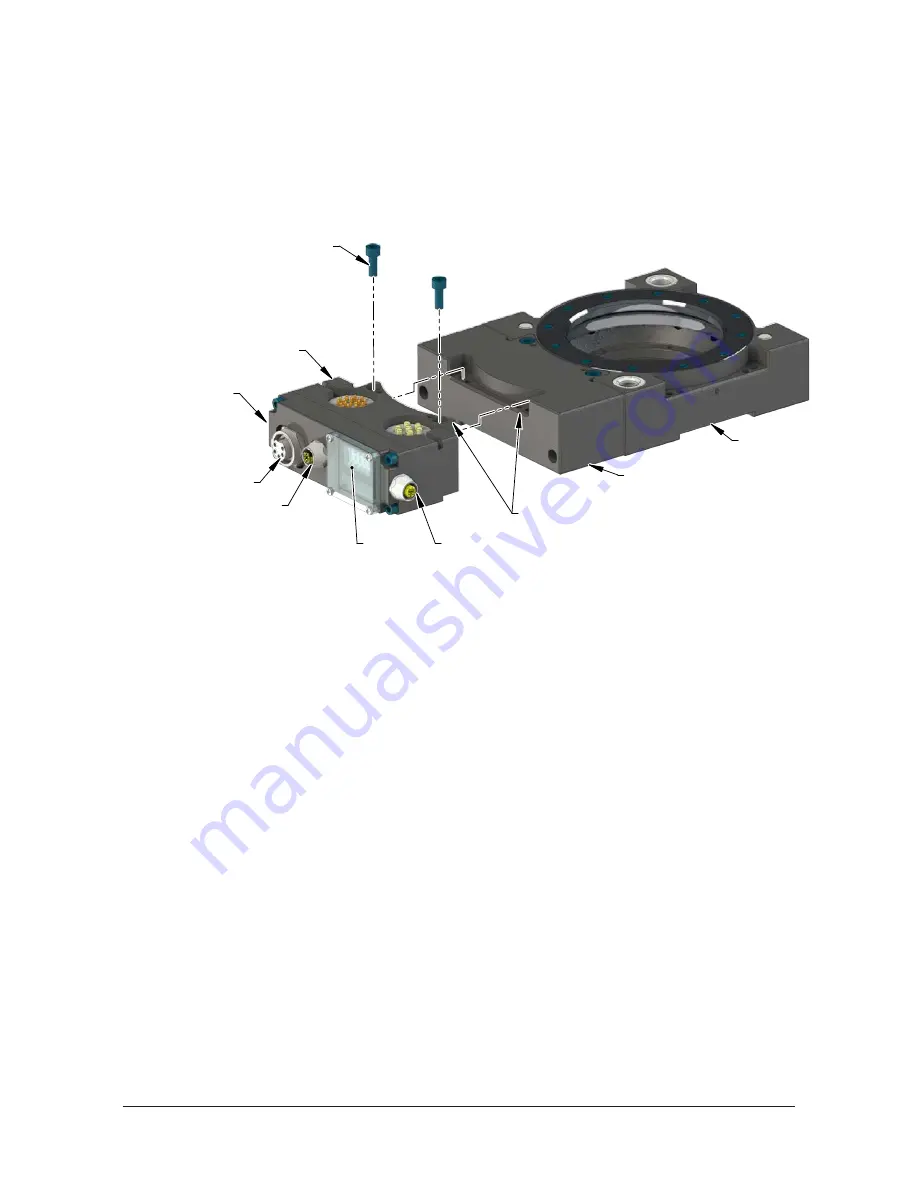

Figure 3.2 —Tool Module Installation

Tool Changer

Valve Adapter on Tool Side

(9121-JR4-T Shown)

Use Ledge Mounting Feature

to Properly Align Module

(2) M6 Socket Head Cap Screw

DL12 Tool Module

Safety Switch Connection

Tool-ID

Power Connection

PROFINET Connection

FE Ground Connection

With M5 Set Screw

(Not Visible)

3.4 Tool Module Removal

Tools required: 5 mm Allen wrench (hex key)

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. Disconnect the safety switch cables from the module.

5. Disconnect the 5‑pin power cable and PROFINET cable connectors from the module.

6. Disconnect the ground from the FE grounding terminal.

7. Set the Tool‑ID. Refer to

Section 3.8—Setting the Tool‑ID

8. Support the module and remove the (2) M6 socket head cap screws and lift up on the module until it

clears the guide pin.

3.5 PROFINET Interface

The PROFINET interface parameters and I/O bitmaps employed in the modules are found in

PROFINET Interface Information

of the manual. These should be thoroughly understood prior to operating

the Tool Changer. A detailed operational sequence is provided in

Section 4.4—Recommended Sequence of

3.6 Utility Schematic

Refer to drawings in

of this manual for customer interface and wiring details for the

Master/ Tool modules.

3.7 Electrical Connections

Refer to drawings in

of this manual for electrical connection and pin/signal

information.