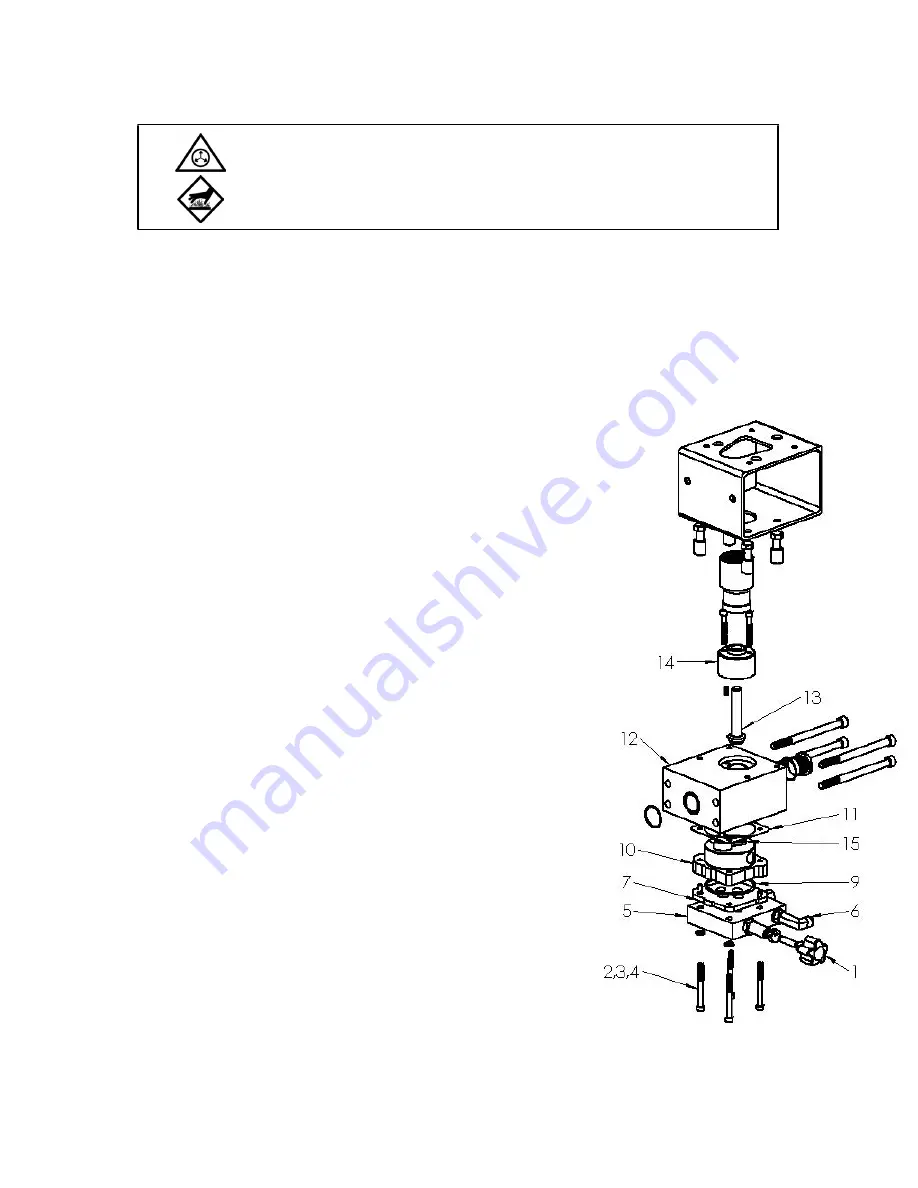

V4 Pump and Flow Control Block Replacement

1. If melt unit is cold, allow to heat for approximately 5 minutes.

2. Depressurize the system by manually actuating the applicator(s).

3. Remove electrical power from the system at the main circuit breaker and at the external source.

4. Disconnect the hose

fl

uid connection(s) from the

fl

ow control block [5]. Disconnect the hose

electrical connection(s) from the bottom of the control box. Set the hose(s) aside.

5. Remove the 4 screws,

fl

at washers and lock washers [2, 3, 4] holding the

fl

ow control block [5].

6. Remove the

fl

ow control block [5], and set it aside. Do not lay the

fl

ow control block

fl

at on any

surface, it may glue itself to the surface.

7. Remove and discard the existing pump [10], gasket [11], wear plate

[8], and pump o-ring [9].

8. Reassemble the pump as follows:

NOTE: V4 pump is shipped with bolts and nuts holding

pump and wear plate together.

a. Remove and discard the bolts and nuts [15] holding the new

pump [10] and wear plate [8] together.

b. Place the 4 screws,

fl

at washers and lock washers [2, 3, 4]

into the

fl

ow control block [5].

c. Cover the new pump o-ring [9] with silicone grease, and

place it into the groove in the pump body.

d. Coat and insert the wear plate o-ring [7] into the groove in

the pump wear plate [8]. Place the pump body [10] onto the

wear plate [8], ensuring not to pinch the o-ring [7].

e. Place the new pump [10] and wear plate [8] into the

fl

ow

control block [5]. Align the assembly with the screws,

fl

at

washers and lock washers [2, 3, 4] so that the bushing

assembly [14] faces away from you and the

fl

ow control

valve faces to the right.

f. Place new gasket [11] on pump [10]. No sealants needed.

9. Align the pump shaft slot on the end of the shaft [13] with the tab

atop the pump [10].

10. Slide the pump assembly into the pump block [12] and tighten the

screws,

fl

at washers and lock washers [2, 3, 4] in a crisscross

fashion.

11. Reconnect hose(s)

fl

uid and electrical connections, and reapply

electrical power to the melt unit.

12. With the pump switch o

ff

, allow the melt unit to heat to operating

temperature.

13. Retighten pump screws to 5.65 – 8.47 N-m (50 – 75 Ibs.-in.).

14. Adjust the adhesive pressure by turning the

fl

ow control knob [1].

Refer to Section 4.2 Adjustments.

15. Test the melt unit, adjust the pressure and check for leaks.

16. Return the melt unit to service.

©Astro Packaging Rev D

D2-15 Manual-19600-10-D215

7-8

WARNING:

Contents at high temperature and pressure. Remove pressure before opening

fi

lter or drain valve to prevent accidental discharge of system pressure. Do not

touch hot surfaces. Failure to follow these instructions may result in severe burns.

Содержание D2-15

Страница 1: ......

Страница 2: ......

Страница 15: ...Dimensions Astro Packaging Rev D D2 15 Manual 19600 10 D215 2 3 ...

Страница 31: ... Astro Packaging Rev D D2 15 Manual 19600 10 D215 4 11 ...

Страница 48: ... Astro Packaging Rev D D2 15 Manual 19600 10 D215 8 5 ...

Страница 50: ... This page is intentionally left blank Astro Packaging Rev D D2 15 Manual 19600 10 D215 8 7 ...

Страница 52: ... Astro Packaging Rev D D2 15 Manual 19600 10 D215 8 9 ...

Страница 54: ... Astro Packaging Rev D D2 15 Manual 19600 10 D215 8 11 ...

Страница 58: ... This page is intentionally left blank Astro Packaging Rev D D2 15 Manual 19600 10 D215 8 15 ...

Страница 61: ... This page is intentionally left blank Astro Packaging Rev D D2 15 Manual 19600 10 D215 8 18 ...

Страница 64: ...Motor Wiring Astro Packaging Rev D D2 15 Manual 19600 10 D215 9 3 ...

Страница 65: ...Wiring Diagram 120V Astro Packaging Rev D D2 15 Manual 19600 10 D215 9 4 D200113 ...

Страница 66: ...Wiring Diagram 240V Astro Packaging Rev D D2 15 Manual 19600 10 D215 9 5 D200113 ...

Страница 67: ... This page is intentionally left blank Astro Packaging Rev D D2 15 Manual 19600 10 D215 9 6 ...