8

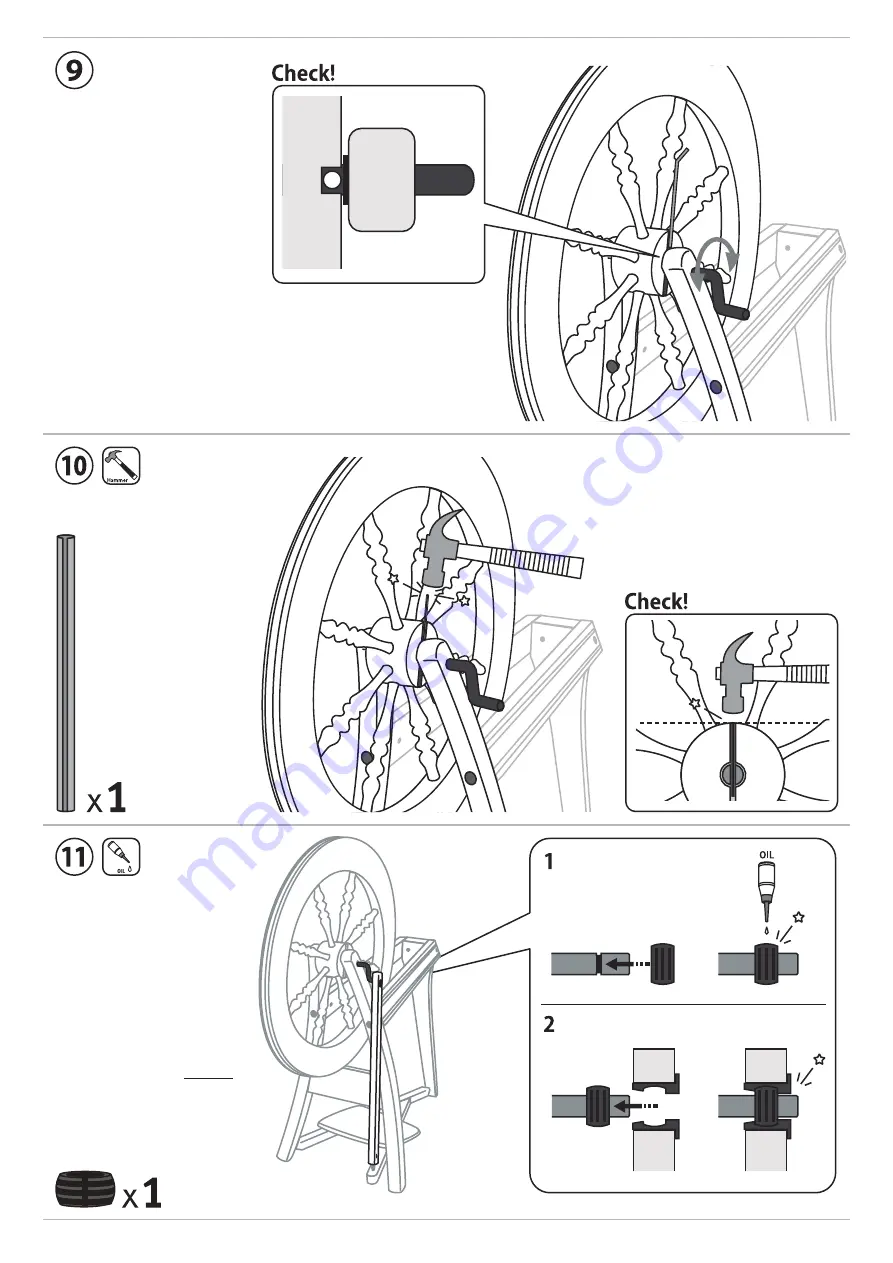

Align the wheel and hole in

the crank shaft with the

groove in the hub using a

lazy kate wire.

Carefully tap the hub

pin through the hub

and crank.

Slide the inner shell of the

conrod universal joint onto

the crank until

it clicks into the groove.

Apply a drop of oil to this

bearing and click the

conrod onto the inner

shell of the conrod joint.

Note: The ball bearings are

sealed for life and do not

require oiling.

Align the wheel and hole in

the crank shaft with the

groove in the hub using a

lazy kate wire.

Carefully tap the hub

pin through the hub

and crank.

Slide the inner shell of the

conrod universal joint onto

the crank until

it clicks into the groove.

Apply a drop of oil to this

bearing and click the

conrod onto the inner

shell of the conrod joint.

Note: The ball bearings are

sealed for life and do not

require oiling.

Slide the inner shell of the

conrod universal joint onto

the crank until it clicks into

the groove.

Apply a drop of oil to this

bearing and click the

conrod onto the inner

shell of the conrod joint.

Note: The ball bearings are

sealed for life and

do not

require oiling.

Содержание TRADITIONAL SPINNING WHEEL

Страница 2: ...2...

Страница 3: ...3 x1 x1 x2 x2 x1 x1 x1 x1 x1 x1 x3 x13 x2 x4 x4 x1 x2 x2 Real Scale Hardware List 3...

Страница 4: ...4...

Страница 17: ...17...