Ascon Tecnologic - KX Line - ENGINEERING MANUAL -Vr.4.0

PAG. 15

[54] LbcA - Condition for LBA enabling

Available:

when [51] LbAt is different from oFF

Range:

uP =

Enabled when the PID requires the maxi-

mum power only.

dn =

Enabled when the PID requires the mini-

mum power only

both = Enabled in both condition (when the PID re-

quires the maximum or the minimum power).

LBA application example:

LbAt (LBA time) = 120 seconds (2 minutes)

LbAS (delta LBA) = 5°C

The machine has been designed in order to reach 200°C in

20 minutes (20°C/min).

When the PID demands 100% power, the instrument starts

the time count.

During time count if the measured value increases more

than 5°C, the instrument restarts the time count. Otherwise

if the measured value does not reach the programmed delta

(5°C in 2 minutes) the instrument will generate the alarm.

]

rEG group - Control parameters

The rEG group will be available only when at least one

output is programmed as control output (H.rEG or C.rEG).

[55] cont - Control type:

Available:

When at least one output is programmed as con-

trol output (H.rEG or C.rEG).

Range:

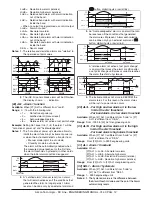

When two control action (heat & cool) are programmed:

Pid =

PID (heat and cool)

nr =

Heat/Cool ON/OFF control with neutral zone

HSEt

HSEt

SP

PV

time

OUTH.rEG

(heating)

OUTc.rEG

(cooling)

off

ON

ON

off

off

ON

When one control action (heat or cool) is programmed:

Pid =

PID (heat or cool);

On.FA = ON/OFF asymmetric hysteresis;

On.FS = ON/OFF symmetric hysteresis;

3Pt =

Servomotor control (available when Output

2 and Output 3 have been ordered as “

M

”).

HEAt - On.FA

OUT

H.rEG

SP

PV

HSEt

time

off

off

C ooL - O n.FA

OUT

C.rEG

SP

PV

HSEt

time

ON

ON

ON

off

off

ON

ON

ON

HEAt - On.FS

OUT

H.rEG

SP

PV

HSEt

HSEt

time

C ooL - O n.FS

OUT

H.rEG

SP

PV

HSEt

HSEt

time

ON

ON

ON

off

off

off

off

ON

ON

ON

Notes: 1.

ON/OFF control with asymmetric hysteresis:

•

OFF when PV > SP

•

ON when PV < (SP - hysteresis)

2.

ON/OFF control with symmetric hysteresis:

•

OFF when PV > (SP + hysteresis)

•

ON when PV < (SP - hysteresis)

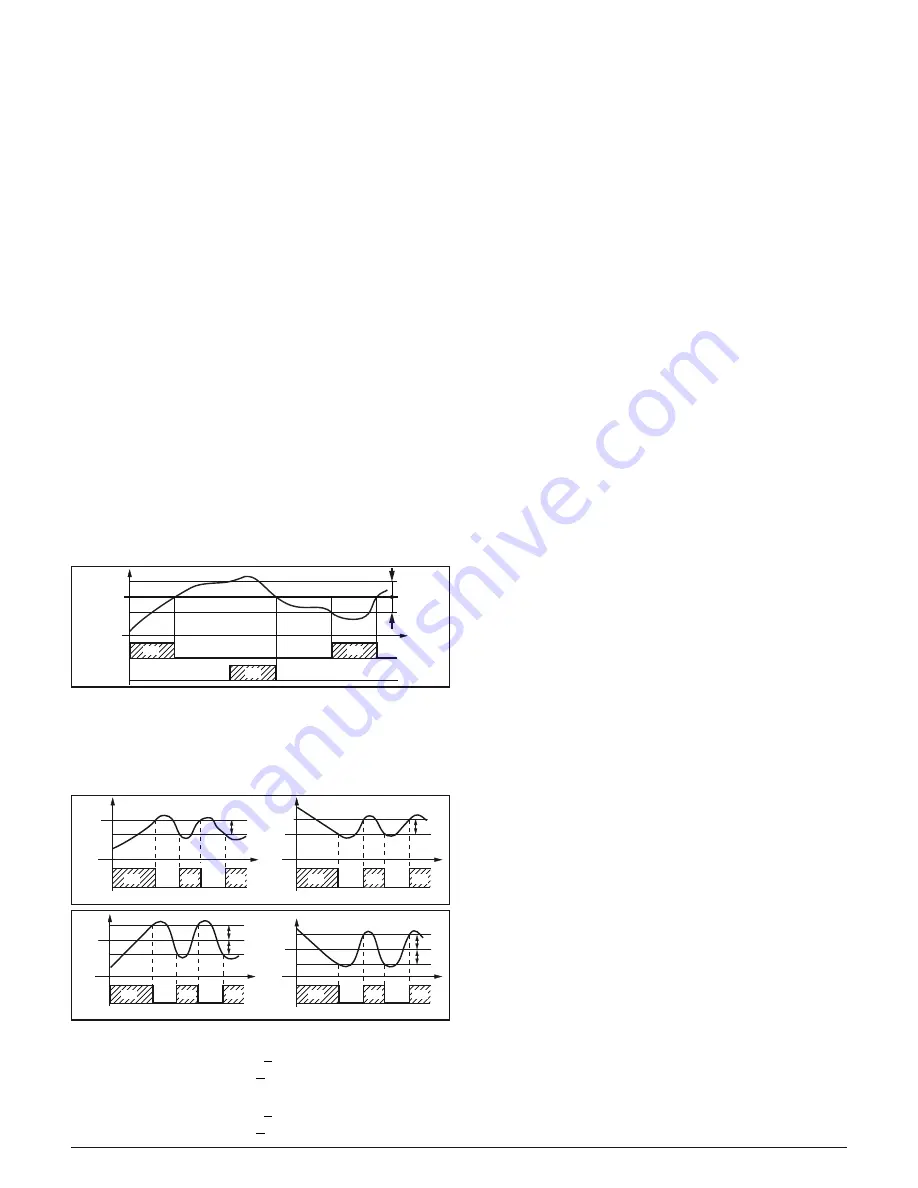

[56] Auto - Auto tune selection

Ascon Tecnologic has developed three auto-tune algorithms:

–

Oscillating auto-tune;

–

Fast auto-tune;

–

EvoTune.

1. The

oscillating

auto-tune is the usual auto-tune and:

•

It is more accurate;

•

Can start even if PV is close to the set point;

•

Can be used even if the set point is close to the

ambient temperature.

2. The

fast type

is suitable when:

•

The process is very slow and you want to be opera-

tive in a short time;

•

When an overshoot is not acceptable;

•

In multi loop machinery where the fast method

reduces the calculation error due to the effect of the

other loops.

3. The

EvoTune

type is suitable when:

•

You have no information about your process;

•

You can not be sure about the end user skills;

•

You desire an auto tune calculation independently

from the starting conditions (e.g. set point change

during tune execution, etc).

Note:

Fast auto-tune can start only when the measured

value (PV) is lower than (SP + 1/2SP).

Available:

When [55] cont = PID

Range:

-4... 8 where:

-4 =

Oscillating auto-tune with automatic restart

at all set point change;

-3 =

Oscillating auto-tune with manual start;

-2 =

Oscillating auto-tune with automatic start at

the first power up only;

-1 =

Oscillating auto-tune with automatic restart

at every power up;

0 =

Not used;

1 =

Fast auto tuning with automatic restart at

every power up;

2 =

Fast auto-tune with automatic start at the

first power up only;

3 =

FAST auto-tune with manual start;

4 =

FAST auto-tune with automatic restart at all

set point change.

5 =

EvoTune with automatic restart at every

power up;

6 =

EvoTune with automatic start at the first

power up only;

7 =

EvoTune with manual start;

8 =

EvoTune with automatic restart at all set

point change.

Note:

All auto-tunes are inhibited during program execution.

[57] Aut.r - Manual start of the auto-tune

Available:

When [55] cont = PID.

Range:

oFF = The instrument is not performing the auto-tune;

on =

The instrument is performing the auto-tune.

[58] SELF - Self-tune enable

The self-tuning is an adaptive algorithm able to optimize

continuously the PID parameter value.

This algorithm is specifically designed for all process subjected to

big load variation able to change heavily the process response.