17

MAINTENANCE SECTION

3. Whenever grasping a tool or part in a vise, always use

leather--covered or copper--covered vise jaws to protect

the surface of the part and help prevent distortion. This

is particularly true of threaded members and housings.

4. Except for bearings, always clean every part and wipe

every part with a thin film of oil before installation.

5. Apply o--ring lubricant to all o--rings before final

assembly.

6. Check every bearing for roughness. If an open bearing

must be cleaned, wash it thoroughly in a clean, suitable

cleaning solution and dry with a clean cloth.

Sealed or

shielded bearings should never be cleaned.

Work

grease into every open bearing before installation.

Assembly of the Throttle Mechanism

1. If the Trigger Assembly (3A) was removed, insert the

shaft of the Trigger into the Motor Housing (1) and

push it all the way into the trigger recess in the

Housing until it stops.

2. Using long reach needle nose pliers to hold the Trigger

Retainer (3B), insert the Retainer into the inlet bushing

opening and install the straight leg of the Retainer in

the hole through the shaft of the Trigger.

3. Install the Inlet Bushing Bezel (6), convex end leading,

onto the Inlet Bushing Assembly (4). Bring the convex

end into contact with the hex at the inlet end of the

Bushing.

4. Spread the opening slightly on the Inlet Bushing

Retainer (7) and install it around the Inlet Bushing with

the tab end nearest to the bushing hex and against the

Bezel.

5. Grasp the hex of the Inlet Bushing in leather--covered

or copper--covered vise jaws with the throttle valve

opening upward.

6. Insert the Throttle Valve Spring (8B), large end

leading, followed by the Throttle Valve (8A), long

stem end trailing, into the valve opening.

7. Place the Throttle Valve Seat (8C) followed by the

Valve Seat Support (8D) in the opening against the

Valve.

8. Using snap ring pliers while compressing the Throttle

Valve Spring and moving the Seat and Support inward,

capture the components by installing the Valve Seat

Retainer (8E) in the Bushing internal groove.

9. Moisten the Inlet Bushing Seal (8F) with o--ring

lubricant and install it on the exterior of the Inlet

Bushing.

10. Remove the assembled Bushing from the vise jaws. If

the Inlet Bushing Screen was removed, use a flat faced

dowel slightly less than 1/2” in diameter to push the

new Screen into the opening at the hex end of the

Bushing.

Assembly of the Motor

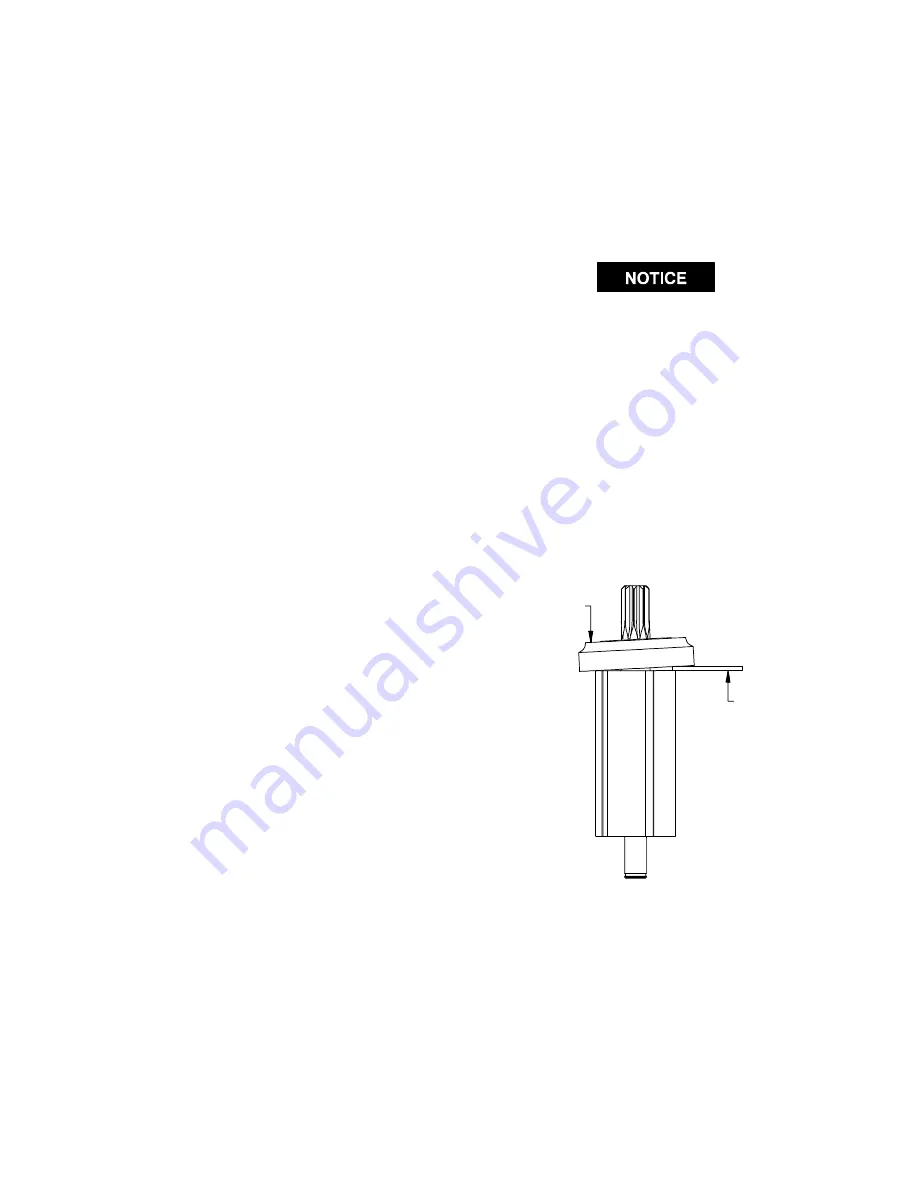

1. Place the Front End Plate (17) on the splined shaft of

the Rotor (15) with the bearing recess away from the

rotor body.

2. Place the Front Rotor Bearing (19) onto the shaft and

using a sleeve or piece of tubing that contacts the inner

race of the Bearing, press the Bearing onto the shaft

until the Front End Plate nearly contacts the rotor body.

In the following step, the measurement must be

made at the end corner of the large rotor body.

3. The clearance between the Front End Plate and Rotor

is critical. While pressing down with your finger on the

outer edge of the Front End Plate on the bearing side,

insert a 0.004” (0.1 mm) feeler gauge between the face

of the rotor body and the face of the End Plate at a

point that is 180 degrees from where the pressure is

applied. Refer to Dwg. TPA1740. To increase the gap,

support the End Plate and lightly tap the rotor shaft

with a plastic hammer; to decrease the gap, press the

Bearing farther onto the rotor shaft.

Measurement of Front End Plate Clearance

(Dwg. TPA1740)

PRESSURE

FEELER

GAUGE

4. Wipe each Vane (16) with a light film of IRAX No. 10

Oil and place a Vane in each slot in the Rotor.

5. One end of the Cylinder Assembly (13) has a notch

that breaks the outer wall and end face of the Cylinder.

With that end trailing, install the Cylinder Assembly

over the Rotor and Vanes against the Front End Plate.

Make certain the Cylinder Alignment Pin (14) enters

the hole in the Front End Plate.

Содержание RG1AA

Страница 13: ...13 SERIES RG2 DRILLS Dwg ATP29 1 ...

Страница 20: ......