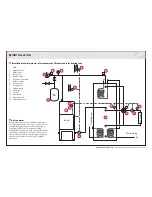

Planning and installation

Planning and installation shall be carried out in a professional manner, attention being

paid to general and local rules and regulations. Operating pressure is max. 1,5 bar.

Before taking the installation into service, and always at the beginning of the heating

season, the following checks shall be carried out:

• that the heating system is fi lled and bled

• that the circulation pump is working

• that the system valves are open

• that the automatic control and safety devices are in working order

• that the chimney has the necessary draught and that the fresh air ventilation

is open.

Safety valve

If a closed expansion vessel has been installed in the radiator system, the safety valve

must be checked 4 times a year. Activate the valve by pressing or turning the control

button and check that water escapes from the overfl ow pipe connecting the valve to

the drain.

Boiler temperature

Th

e higher the temperature on the boiler the greater the capacity to generate hot water

for the taps from the separate hot water tank (recommended setting = 80°C). Th

e

temperature on the boiler must never be set so low that condensation forms in the

boiler.

Before you begin heating, the heating system must be fi lled with water.

To fi ll the system, do as follows:

1. Open all shut-off valves, including the shunt valve.

Th

e pump must be switched off .

2. Fill the boiler and the radiator system with water.

Bleed the system at the radiators.

3. Once the system is fi lled completely, the circulation pump can be started and

heating can begin.

4. When the boiler water has reached its pre-set operating temperature, the pump

should be stopped and the system bled at the radiators once again. Th

is should be

repeated several times.

Remember that much air is enclosed in tap water. Th

e enclosed air volume may reach

as much as 10%, which explains why bleeding takes time – especially where there are

large water volumes. A closed system shall be fi lled until the pressure gauge indicates

the correct system pressure, i.e. the distance from the pressure gauge to the highest ra-

diator in meter times 0,1 which gives the system pressure in bar. Adjust the red needle

of the pressure gauge to the same value as the big needle.

ARITERM SWEDEN AB

Installation, Operation and Maintenance - 2007.10.26- 7/12

WATER PIPING

FILLING OF WATER