Important Information .....................................................................2

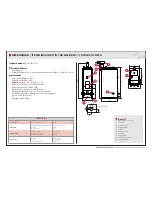

Dimensions / Items Included / Technical Data ............................3

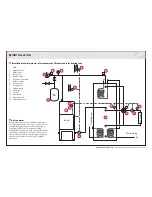

Operating Principle ..........................................................................4

Installation ..................................................................................... 5-6

Water Piping ................................................................................. 6-7

Filling of Water .................................................................................7

Maintenance ......................................................................................8

Storage Planning ...............................................................................9

Installation Protocol .......................................................................10

Declaration of Conformity.............................................................11

Notes ..............................................................................................11

•

Keep this instruction manual readily available for future use.

•

Read the instructions carefully before taking your pellets installation into service.

•

Th

e capacity of the burner is calculated according to the maximum volume of pel-

lets that can be fed to and burnt in the burn pot during 1 hour (based on a normal,

average wood pellets quality as described in our fuel specifi cation)

•

Follow these instructions carefully and carry out care and maintenance work as

recommended.

Noti

fi

cation to building authority

Attention! W

hen you change heating installation this must always be

communicated to the local building authorities.

Sweeping

According to the fi re protection laws a chimney shall be swept regularly. Th

is is done

by the local chimneysweep.

Sweeping of the boiler shall be carried out in such a

manner that good operating

economy is achieved. (see under ”Maintenance”) Prepare

to chimney-sweeping by turning off the boiler at least one hour before cleaning to

minimize the amount of glowing ash.

Warning!

Make sure to cut the power supply to the boiler before removing the burner housing.

Maintenance contract

Ariterm recommends the boiler installation to be made by a company with professio-

nal competence. For more information please contact your Ariterm retailer.

Replacing of spare parts

Ariterm recommends that replacing of spare parts is made by authorized serviceman

of Ariterm retailer. Th

e retailer supplies required spare parts and authorized service-

man makes the necessary adjustments and combustion gas analysis when replacing

spare parts.

ARITERM SWEDEN AB

Installation, Operation and Maintenance - 2007.10.26- 2/12

CONTENTS

IMPORTANT INFORMATION