D-6

MAINTENANCE AND TROUBLESHOOTING

D-6

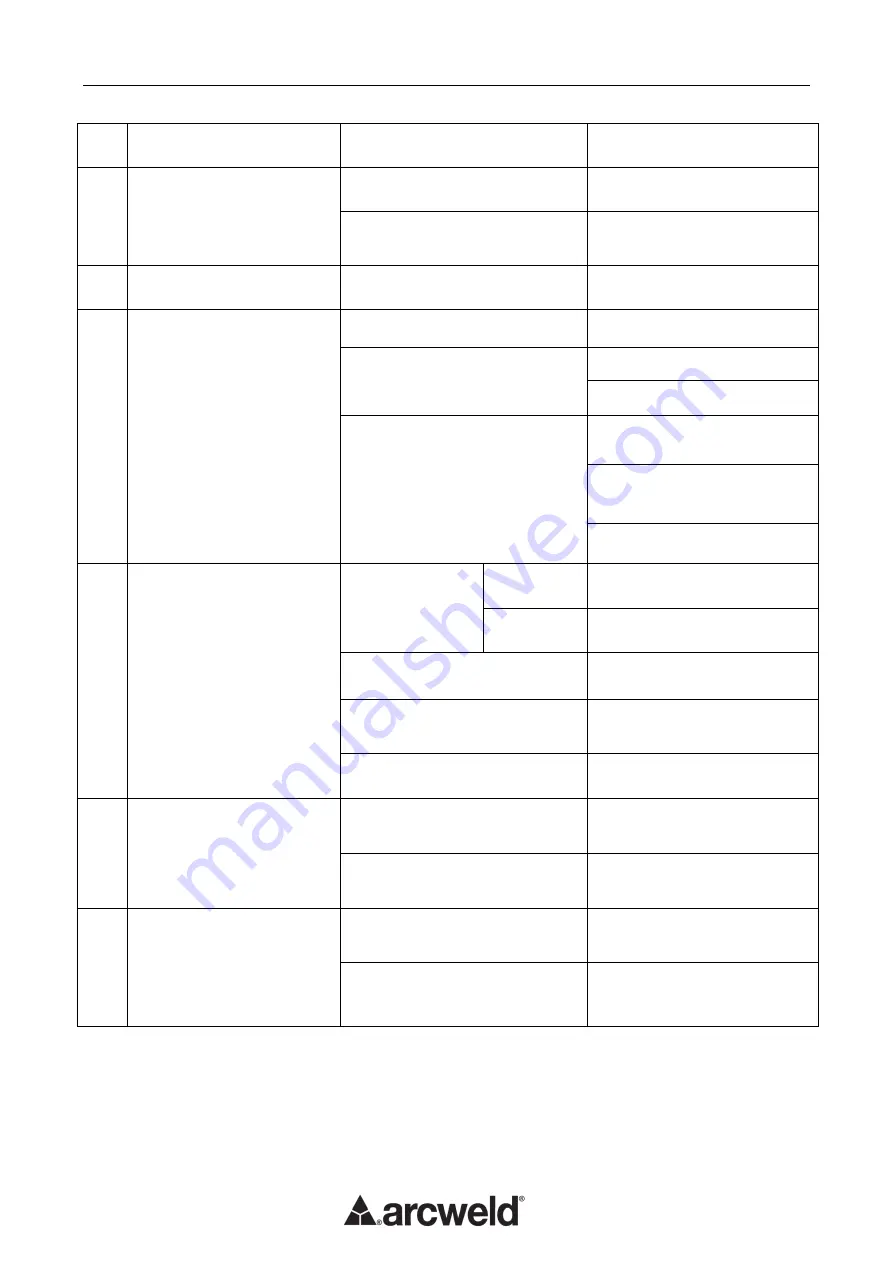

Item

PROBLEMS(SYMPTOMS)

POSSIBLE CAUSE

RECOMMENDED COURSE OF

ACTION

8

The welding parameters can not

be adjusted anyway.

The welding current potentiometer on

the front panel damaged

Repair or change the potentiometer

The software died.

Press any buttons on front panel for

5 seconds for resetting software.

9

The penetration of molten pool is

not enough(MMA).

The welding current adjusted too low.

Increase the welding current.

10

Arc blow

Airflow disturbance.

Protect from airflow dissipating

sheilding gas.

The electrode eccentricity.

Adjust the electrode angle.

Change the electrode.

Magnetic effect.

Incline the electrode to the opposite

side of the magnetic blow .

Change the position of work clamp

or add work cable in the second

side of workpiece.

Use the short arc operation

11

The alarm light is on

Over heat protection

Over welding

current.

Reduce the welding current output

Exceed duty

cycle.

Reduce the duty cycle (interval of

weld time).

Undervoltage, overvoltage,

overcurrent protection circuits work.

Check if the input power is correct.

Output is in the short circuit situation.

Check and fix the short circuit issue

outside machine.

The thermostat is faulty.

Check the thermostats inside

machine.

12

Shielding gas operation is

abnormal.

Gas solenoid control circuit is faulty.

Check relevant components around

it on main PCB board.

Gas solenoid power connector is

loose or damaged.

Repair or replace the connectors of

gas solenoid.

13

No high frequency spark occurs

after closing the trigger of TIG

torch.

The control circuit of arc start is faulty.

Check relevant components around

it on main PCB board.

The high frequency arc start board is

faulty.

Check relevant components around

it on arc start board.

Содержание TIG 205 DC

Страница 5: ...iii SAFETY iii ...

Страница 6: ...iv SAFETY iv ...

Страница 25: ...E 1 DIAGRAM E 1 ...