98

1. Turn the ignition switch ON and listen for a momen-

tary “whirring” sound of the pump building pressure.

If the sound is heard (10 seconds), no electrical

checks are necessary. Turn the ignition switch OFF.

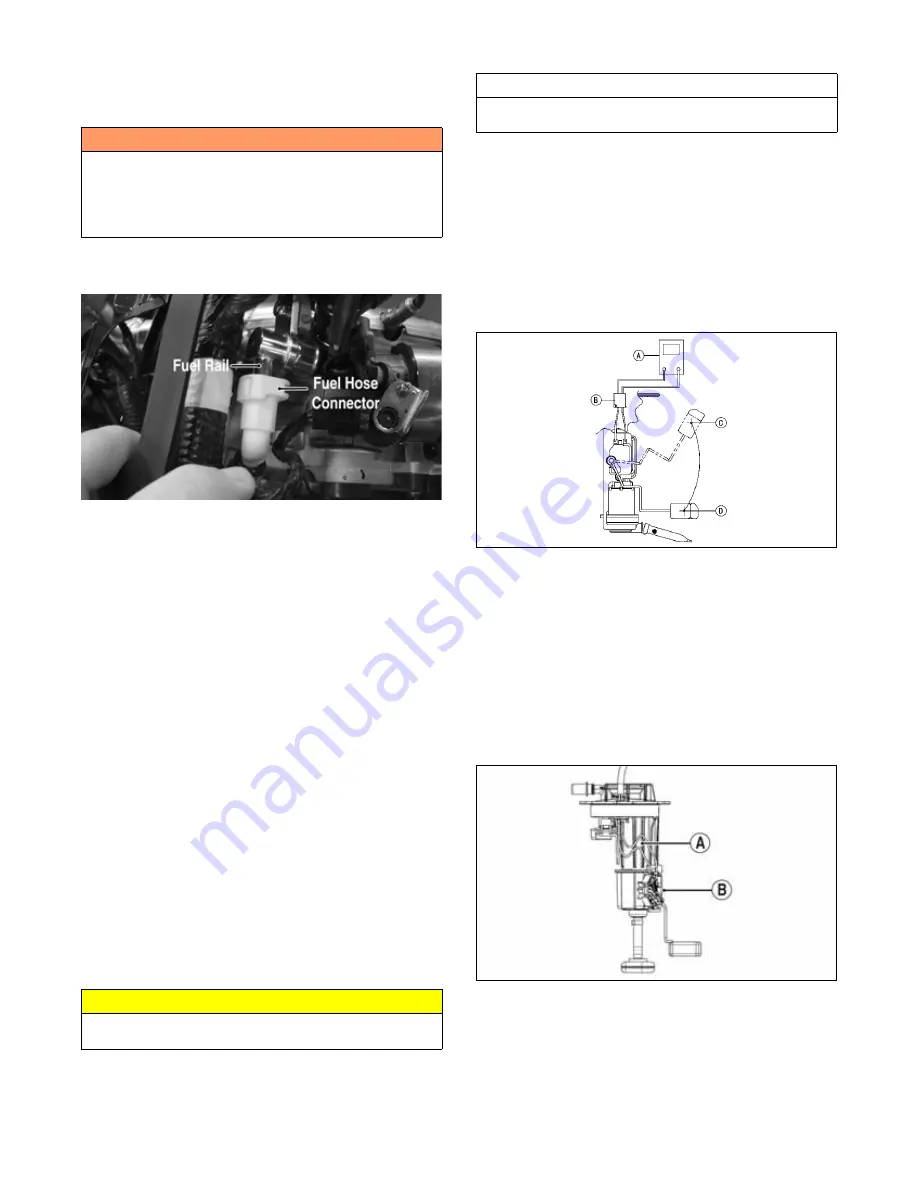

2. Disconnect the fuel hose from the fuel rail; then

install a suitable pressure gauge.

CF730A

3. Reconnect the fuel pump electrical connector; then

turn the ignition switch to the ON position. The fuel

pressure should build until the pump shuts off. Pres-

sure should read 3.0 kg-cm

2

(43 psi).

4. If the pump is not running, disconnect the fuel

pump/sensor connector.

5. Connect a multimeter to the power supply leads with

the red tester lead to the orange/red wire and the

black tester lead to the black wire; then turn the igni-

tion switch to the ON position. The meter should

read battery voltage. If battery voltage is indicated

and the fuel pump does not run, replace the pump

assembly. If no battery voltage is indicated, check

the ECM and the vehicle tilt sensor.

REMOVING

1. Remove the rear rack and fenders (see Steer-

ing/Body/Controls); then disconnect the power sup-

ply/fuel hose connector.

2. Disconnect the fuel hose and fuel pump connector.

3. Remove the screws securing the fuel pump to the gas

tank; then make a reference mark on the fuel pump

and tank.

4. Lift out the fuel pump assembly carefully tilting it for-

ward to clear the voltage regulator; then guide the pump

and float lever through the opening in the gas tank.

5. Using duct tape or other suitable means, cover the

fuel pump opening.

INSPECTING

1. Inspect the fuel screen and blow clean with low pres-

sure compressed air.

2. Move the float lever and check for free movement.

The float assembly should return to the lower posi-

tion without force. If not, replace the fuel pump

assembly.

3. Test the fuel level sensor by connecting a multimeter

(A) to the fuel level sensor leads (B); then select

OHMS. The multimeter should show 5 ohms at full fuel

position (C) and 95 ohms at empty fuel position (D).

ATV2116

NOTE: If readings are erratic, clean the resistor

wiper and resistor with clean alcohol and retest. If

still not correct, replace the fuel level sensor.

Replacing Fuel Level Sensor

To replace the fuel level sensor, use the following proce-

dure.

1. Cut the two blue wires (A) in the location shown.

2. Slide the existing fuel level sensor assembly (B) up

and off the fuel pump assembly housing.

XR257A

3. Keeping the float attached to the float arm; then

remove the float arm from the existing fuel level sen-

sor. Press the float arm into the new fuel level sensor

assembly. Ensure it locks into place.

! WARNING

Gasoline may be under pressure. De-pressurize the fuel

system by disconnecting the fuel pump electrical con-

nector and running the engine until it stalls. Place an

absorbent towel around the connector to absorb any

gasoline when disconnecting.

CAUTION

Take care not to damage the float or float arm or

replacement of the entire assembly will be necessary.

AT THIS POINT

If the pump has failed earlier test and must be replaced,

proceed to INSTALLING.

Содержание VLX 70002017

Страница 1: ...2017 S SERVICE ERVICE MANUAL ANUAL www arcticcat com...

Страница 137: ...136 NOTES...