15

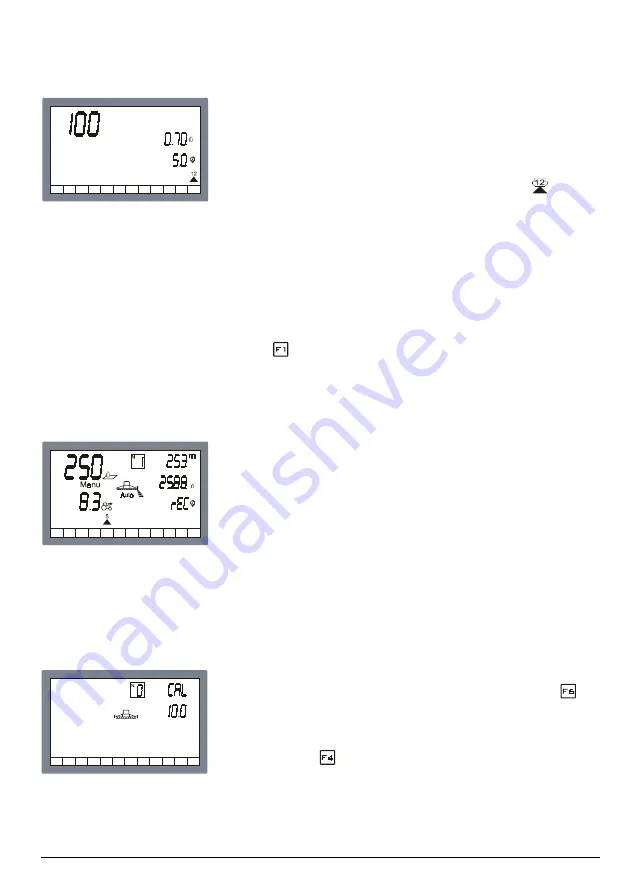

Fig.18:

Setting the calibrated returns

If the operator wishes to use a non-ISO nozzle but still be able

to select the ISO nozzles directly, he can access a nozzle

known as "USER" in which he can set the data of the nozzle in

use.

To do this, display the nozzle selection screen as described

earlier and bring the flashing nozzle symbol into the

posi-

tion (fig.16); the display will contain the indication of the

number of litres per minute delivered by the nozzle at a given

pressure (in the example, the nozzle delivers 0.70 l/min at a

pressure of 5.0 bar).

The number in the top left-hand corner indicates the distribu-

tion value (in litres/hectare) which the computer will maintain

with the nozzle selected. To change the last value set, simply

press the

key and use the modification key.

N.B.: for each nozzle, BRAVO30X always sets the last distribu-

tion value used with that nozzle.

Valves with calibrated returns

If the unit is fitted with valves complete with calibrated return,

and if BRAVO30X has been programmed for operation with

calibrated return during installation of the system, at each

nozzle change the flashing message

rEG

appears on the right

of the display.

This reminds the user that he has to perform a new procedure

to adjust the calibrated returns.

N.B.: The calibrated return adjustment procedure is necessary

to allow the computer to adjust and display the distribution

correctly when one or more section bars are closed.

Setting the calibrated returns

Setting of the calibrated returns is started by keeping the

function key pressed for 1 second (fig.18).

Open all the section valves and the master valve; the flow-rate

value currently read by the flow-meter (10.0 in the example) is

displayed beside

.

Close the first section valve: the flow-rate information before

the closure is frozen on the display, while the flow-rate value

currently read by the flow-meter (with the section valve dis-

charging on the calibrated return), given by the sum of the flow-

rates to the boom and the tank, by means of the calibrated

Fig.17: Requesting calibration

of the calibrated returns

Fig.16:

"USER" nozzle