24

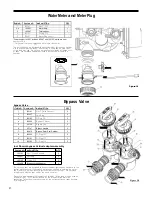

ITEM NO.

ORDER NO.

DESCRIPTION

QTY.

1

102548

Spacer Stack Assy

1

2

101613

Drive Cap Assy.

1

3

102167

O-Ring 228 -Drive Cap Assy.

1

4a

102292

Piston Downflow Assy.

1**

4b

102297

Piston Upflow Assy.

1

5

102296

Regenerant Piston

1

6

102192

O-ring 337-tank

1

7

102165

O-ring - Distributor Tube

1

8

101189

PM 6.0 Back Plate

1

9

102892

Service Wrench - Not Shown

1

5

Front Cover and Drive Assembly

7

9

P/N: 110038

8

ITEM NO.

ORDER NO.

DESCRIPTION

QTY.

1

103473

PM 6.0 Cover Assy w/Label

1

2

102096

Motor

1

3

101262

Drive Bracket & Spring Clip

1

4

109807

PM 6.0 - PC Board

1

5

101746

Drive Gear 12x36

3

6

101459

Drive Gear Cover

1

7

103724

Relay Kit Option Installed

1

8

102385

Relay Only

1

9

110038

Battery

1

Not Shown

102653

Transformer 110V-12V

1

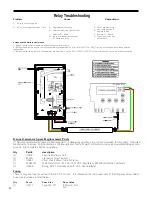

After completing any valve maintenance involving the drive assembly or the drive cap assembly and pistons,

press and hold NEXT and REGEN buttons for 3 seconds or unplug power source jack from the printed

circuit board (black wire) and plug back in. This resets the electronics and establishes the service piston

position. The display should flash all wording, then flash the software version (ex: 214) and then reset the

valve to the service position.

Figure 14

Drive Cap Assembly, Downflow Piston, Regenerat Piston and

Spacer Stack Assembly

8

3

1

1

4b

*102292 is labeled with DN and 102297 is labeled with UP.

Note: The regenerant piston is not used in backwash only applications.

**Standard Option.

2

5

4a

7

6

6

3

8

7

Figure 15

Do not use vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A silicone lubricant may be used on black o-rings but is not necessary.

Avoid

any type of lubricants, including silicone, on red or clear lip seals.

After completing any valve maintenance involving the drive assembly or the drive cap assembly and pistons, press and hold NEXT and REGEN buttons for 3 seconds

or unplug power source jack from the printed circuit board (black wire) and plug back in. This resets the electronics and establishes the service piston position.

The display should flash all wording, then flash the software version (ex: 214) and then reset the valve to the service position.

Содержание PurAzone A03

Страница 1: ...PurAzone A03 Filtration PurAzone A03 Filtration Filter Manual Owner s Filter Manual 2013 2014...

Страница 5: ...5 Figure 2 Figure 4...

Страница 14: ...13 NEXT to go to Step 15S...

Страница 18: ...17 RETURN TO NORMAL MODE...

Страница 20: ...16 NEXT to go to Step 10CS...

Страница 34: ...28...