18

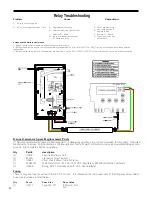

aUX MaV SeP SOUrce

SeT

TrIGGer

aUXIlIarY InPUT

STeP 12cS

STeP 13cS

STeP 12cS

–

Seperate source selection requires connection of motorized alternator valve

(MAV) to Auxiliary Drive two

‑

pin connection on board.

Auxiliary MAV Drive set to operate with a Seperate Source trigger. Auxiliary MAV transitions

to Bypass before the start of regen cycle #1, AFTER Alternator MAV motor transition.

Auxiliary

MAV transitions back to Service at the completion of the last programmed regen cycle, once

the Valve Motor deactivates and BEFORE Alternator MAV transition (if scheduled). Auxiliary

MAV will NOT automatically return to Service while manually stepping valve through regen,

MAV will remain in Bypass until regen cycle end. Press NEXT to go to Step 16CS. Press

REGEN to return to previous step.

STeP 13cS

–

This display will be available to select the use of an outside signal to control the

SeT

ON 0

reG

initiation of a regeneration. Selection only matters if a connection is made to the two pin

connec

-

tor

labeled DP SWITCH located on the printed circuit board. Following is an explanation of the

options:

• IMMED REGEN – If the dP switch is closed for an accumulative time of 2 minutes, a

regeneration will occur immediately.

• DELAY REGEN – If the dP switch is closed for an accumulative time of 2 minutes, a

regeneration will occur at the schedule regeneration time.

• HOLD REGEN – If the dP switch is closed a regeneration will be prevented from occurring.

• OFF - Factory setting is off

Press NEXT to go to Step 14CS. Press REGEN to return to previous step.

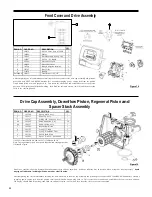

bacKWaSH

SeT

cYcle 1

rInSe

STeP 14cS

STEP 15CS

STeP 14cS

–

Press the

or

buttons until selection of first cycle appears in left upper cor

-

ner, in this example BACKWASH is selected. Press NEXT to go to Step 15CS. Press

REGEN

to return to previous step.

STEP 15CS –

Press the

or

buttons until selection of second cycle appears in left upper

SeT

cYcle 2

corner, in this example RINSE is selected. Press NEXT to go to Step 16CS. Press REGEN

to

return to previous step.

draW dn

STeP 16cS

STeP 16cS

–

Press the

or

buttons until selection of third cycle appears in left upper

SeT

cYcle 3

corner, in this example regenerant DRAW DN is selected. Press NEXT to go to Step 17CS.

Press REGEN to return to previous step.

end

SeT

cYcle 4

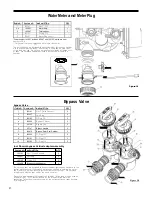

alT FIll TrIGGer

SeT

reGenS

OFF

alT FIll aMOUnT

STeP 17cS

STeP 18cS

STeP 19cS

STeP 17cS

–

Press the

or

button until last regeneration cycle; END appears (up to 9

regeneration modes are possible).

end must be selected as last cycle.

Press NEXT to go

to Step 18CS.

STeP 18cS

–

Press the

or

button to select number of standard regenerations

which would trigger one alternate brine fill amount. Range: 1

‑

99.

Factory setting is

Off.

Press

NEXT to go to Step 19CS.

STeP19cS

–

Select amount of salt to be used when alternate regeneration requested. This

SeT

15.0

lbS

screen is not displayed if off is selected in previous step. Softener Range 0.1–200 lbs. Filter

Range 0.05–20.0 Gallons.

Содержание PurAzone A03

Страница 1: ...PurAzone A03 Filtration PurAzone A03 Filtration Filter Manual Owner s Filter Manual 2013 2014...

Страница 5: ...5 Figure 2 Figure 4...

Страница 14: ...13 NEXT to go to Step 15S...

Страница 18: ...17 RETURN TO NORMAL MODE...

Страница 20: ...16 NEXT to go to Step 10CS...

Страница 34: ...28...