22

Lightning protection

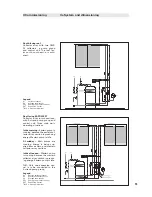

In the storage tank or the wa-

ter heater, very high domestic

hot water temperatures can

sometimes arise. For protec-

tion against scalding at the stor-

age tank output, a thermostatic

3-way mixing valve is to be in-

stalled and configured so that

Scald protection

Under certain operating condi-

tions, solar systems may over-

heat during operation. This is re-

sponded to by the safety valve.

For example:

– No demand for energy from

the solar storage tank, e.g. the

users are on summer holiday.

– The solar system was dimen-

sioned to also provide space

Overheating protection (if not an intrinsically safe system)

the temperature at the tap is

limited to around 50°C.

This mixer (TMV) should be

installed in close proximity to

the storage tank. It must be en-

sured that there is equal water

pressure at both of the mixer's

inputs.

heating in the winter months,

thus there is an energy surplus

in summer.

The surplus energy can be dis-

posed of as follows:

– Heat dissipation during the

night via the solar collectors,

i.e. in the night, the solar circuit

pump activates and cools the

storage tank via the collector.

– The surplus energy is trans-

ferred to a radiator or swim-

ming pool.

Overheating protection is guar-

anteed by setting the desired

temperatures at the solar con-

troller: see solar controller in-

struction manual.

As a general rule, all electrical

devices must be earthed with

a metal housing. This also ap-

plies to solar systems. Pump

group, pipes, storage tank and

collectors must be equipped

with equipotential bonding, i.e.

they must be connected to earth

just like normal water pipes. The

earthing requires a highly con-

ductive connection between the

earthing point and the collector.

The installation of earthing ter-

minals can be realised at the

collector frame. On both the sup-

ply and return sides, the solar

circuit piping is to be connected

to the building's equipotential

bonding via a short route.

Connect the connector to the

collector's lightning protection

connections.

For system sizes < 200m2 (gross

surface area), connect a light-

ning conductor on the left and

the right. For system sizes >

200m2 (gross surface area), add

an additional connection to a

lightning conductor for every

200m2.

Note:

It is imperative to observe

the local regulations.

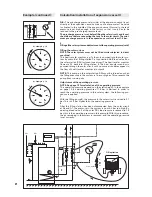

Safety valve

For OWR collectors, safety

valves with 6.0 bar activation

pressure should be installed.

Dimensioning

Dimensioning of safety valves

occurs in accordance with the

general guidelines for 6 bar de-

activation pressure:

- Safety valve

1/2”

max. 75kW

- Safety valve

3/4”

max. 150kW

- Safety valve

1”

max. 445kW

Positioning

Ahead of the shut-off valves in

the solar supply or return.

The pressure capacity of the

expansion vessel must suit the

activation pressure of the safety

valve (SV), e.g. SV activation

pressure 6.0 bar = min. expan-

sion vessel pressure capacity 6.0

bar; smaller expansion vessels

have higher pressure capacity.

Closed systems must be

equipped with an additional

safety valve in the solar circuit.

It must be ensured that the con-

nection between the solar col-

lectors and the safety valve can-

not be shut off. In order to pre-

vent the heat transfer medium

from boiling too often, a safety

valve with shut-off pressure of

6 bar is to be provided for, i.e.

all system components must be

designed and approved for this

pressure.

Lay the connections leading to

the safety valve in such a way

that no dirt or the like can accu-

mulate within them. Ensure that

there are no prohibited constric-

tions, and no pipe bends small-

er than 3d.

II Commissioning

IId Protective devices

Wind load calculations are to be carried out as per local regulations (see also table on page 4).

Wind load calculations