CHAPTER 1: SYSTEM DESCRIPTION

THIN-LINE

®

SERIES 180M WELD HEADS

1-4

990-133

Section III. Welding Capabilities

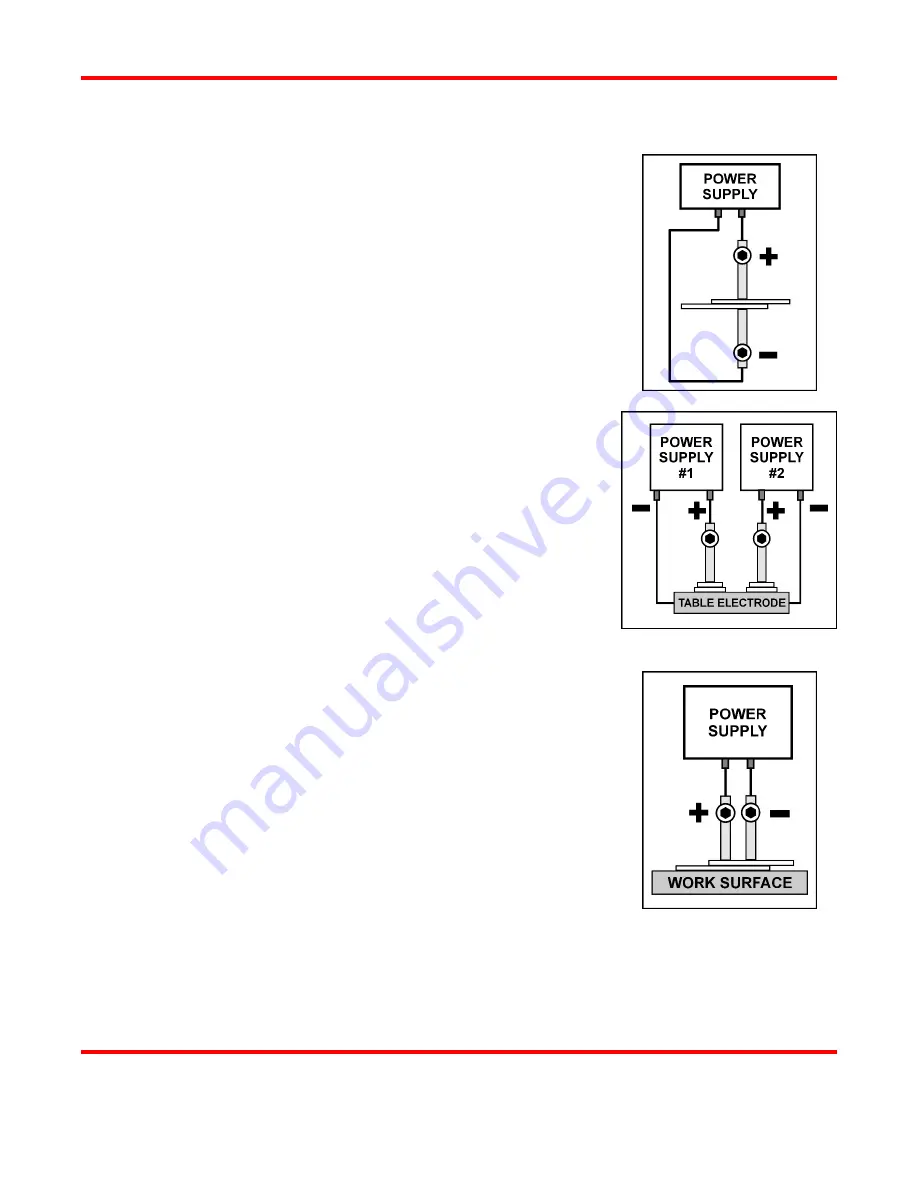

Opposed Welding

With opposed welding, the top and bottom electrodes are used to hold

the parts and provide the current path. Weld current flows from one

electrode through both parts to the other electrode.

An opposed weld is preferred over other configurations because it is

easier to set up and the current path is more easily controlled. It should

be used whenever possible.

Dual-Opposed Welding

This method of welding uses two opposed welds being made on a

single part, using two separate weld energy power supplies. Weld

energy can be delivered in a simultaneous or alternate fashion,

depending on your manufacturing requirements. Opposed welding

provides maximum weld strength repeatability.

The Table Electrode, or a user supplied fixture, acts as a support for the

workpieces in step welding. If the Table is insulated from the

workpieces, there is no possibility of shunting current away from the

(-) electrode.

Series Welding

In series welding applications, both electrodes contact the

same

surface

of each workpiece. The weld current flows from one electrode through

the workpiece to the other electrode. This technique is used to weld

workpieces which have only one surface accessible.

The work surface, or a user supplied fixture, acts as a support for the

workpieces in series welding. If the Table is insulated from the

workpieces, there is no possibility of shunting current away from the

(-) electrode.

Содержание THIN-LINE 180 M Series

Страница 1: ...990 133 REV F WELD HEAD THINLINE 180 M SERIES OPERATION MANUAL ...

Страница 34: ......

Страница 38: ......

Страница 42: ......

Страница 44: ...AMADA MIYACHI AMERICA INC 1820 South Myrtle Ave Monrovia CA 91016 U S A TEL 1 626 303 5676 FAX 1 626 358 8048 ...