CHAPTER 3: OPERATING INSTRUCTIONS

THIN-LINE

®

SERIES 180M WELD HEADS

990-133

3-3

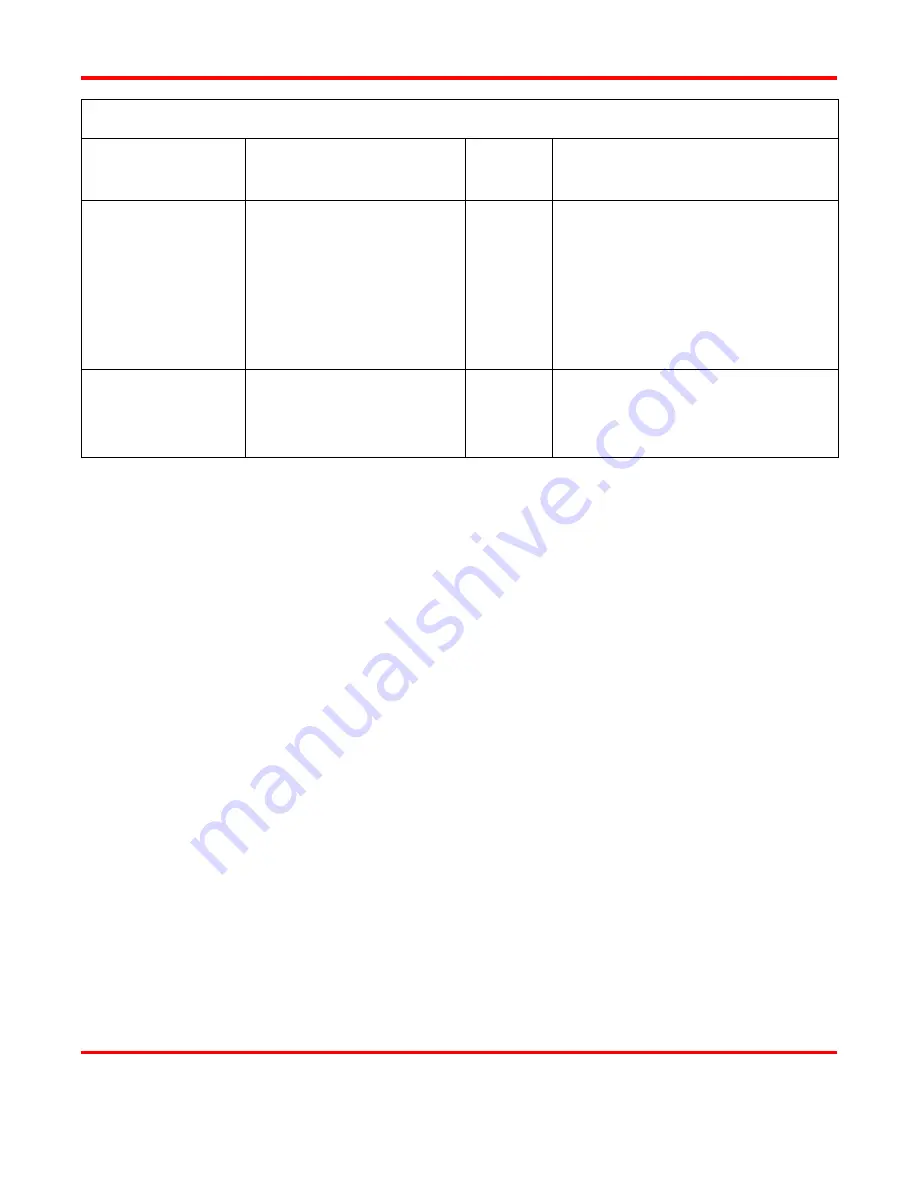

WELDHEAD TROUBLESHOOTING GUIDE

SYMPTOM

OR

PROBLEM

PRIMARY CAUSE

Weldhead-Related Cause

PRIORITY*

SOLUTION

Sparking

Excess Current/Energy

Insufficient Force

Poor Weldhead Follow-up

Electrode Tip Shape

Wrong Electrode Material

Dirty Electrodes

1

1

1

1

2

2

Decrease current/energy in steps of 5-10%

Increase force in steps of 10-20%

Reduce mass of top electrode holder

assembly

***

Use constant area electrodes or shape to

suit application

Check Electrode/Material Selection Guide

Clean electrodes and/or parts to be welded

Warping

Excess Welding Time

Excess Force

Electrode Tip Shape

1

1

2

Decrease Welding Time (A.C. Welding)

Decrease force in steps of 10-20%

Use constant area electrodes or shape to

suit application

**

In most cases capacitor discharge welds do not have a significant nugget.

***

For non-Miyachi Unitek weld heads.

A certain amount of experimentation is necessary to achieve the proper welding force setting for a

specific application. The following are some general rules to make quality welds:

a.

Larger parts require higher force.

b.

Larger diameter electrode faces require higher force.

c.

Higher electrode forces require higher weld currents (energy).

Содержание THIN-LINE 180 M Series

Страница 1: ...990 133 REV F WELD HEAD THINLINE 180 M SERIES OPERATION MANUAL ...

Страница 34: ......

Страница 38: ......

Страница 42: ......

Страница 44: ...AMADA MIYACHI AMERICA INC 1820 South Myrtle Ave Monrovia CA 91016 U S A TEL 1 626 303 5676 FAX 1 626 358 8048 ...