Installation

803447

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Connecting to Central Pay System

IMPORTANT: Any central pay device and related

installation wiring that is connected to the washer

must maintain the Electromagnetic Compatibility

(EMC) of the washer in order to comply with the

appropriate national EMC regulatory

requirements. The central pay device and related

wiring, as a minimum, must meet the emission

requirements of EN55014-1 and the immunity

requirements of EN55014-2.

Start Pulse Input Wiring Connections

Use 511478 Remote Vend Wire Harness, supplied in

accessories bag, to connect input to control

(pin 1 – black; pin 2 – red).

The start pulse is an open collector input to the control.

The start pulse input is active when the input of the

H11L1 optocoupler is energized. The start pulse is

considered valid if it is at least 15 msec. in length with

a maximum length of 1 sec. The minimum time

between start pulses is 25 msec. The minimum active

input current for a start pulse is 3 mA and the

maximum active input current is 30 mA. Refer to

wiring diagram for connections to control.

Available Output Wiring Connections

Use 511478 Remote Vend Wire Harness, supplied in

accessories bag, to connect output to control

(pin 3 – white/red; pin 4 – orange/black).

The available output is opto-isolated with an open

collector device (4N25) that provides a signal to an

external vending device such as a central pay system.

When active it indicates that the washer is not

currently in use and is available to use. The available

output is limited to 5 mA maximum at 28 VDC

maximum. Refer to wiring diagram for connections to

control.

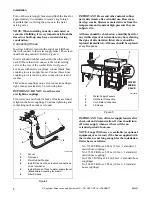

NOTE: Wiring to the central pay system should

exit machine through hole in rear of control

cabinet. Refer to

Figure 14

.

Figure 14

Step 8: Check Installation

Refer to

Installer Checklist

on the back cover of this

manual and make sure that washer is installed

correctly.

Run washer through one complete cycle to make sure

it is operating properly.

FLW2250N

1

Run wiring from central pay system through

here.

1