803447

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Contact Information

If service is required, contact the nearest Factory

Authorized Service Center.

If you are unable to locate an authorized service center

or are unsatisfied with the service performed on your

unit, contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

www.comlaundry.com

Phone: +1 (920) 748-3121

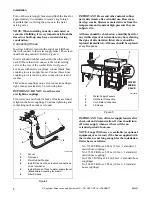

Figure 22

When calling or writing about your unit, PLEASE

GIVE THE MODEL AND SERIAL NUMBERS. The

model and serial numbers are located on the

nameplate. The nameplate will be in the location

shown in

Figure 22

.

Date Purchased ____________________________

Model Number ____________________________

Serial Number ____________________________

Please include a copy of your bill of sale and any

service receipts you have.

If replacement parts are required, contact the source

from where you purchased your washer or call

+1 (920) 748-3950 for the name and address of the

nearest authorized parts distributor.

FLW2123N

1

Nameplate

FLW2123N

1

To reduce the risk of serious injury or death,

DO NOT repair or replace any part of the unit

or attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have

the skills to carry out.

W329

WARNING