15

2480 Remote Intensifier Tooling Alcoa Fastening Systems

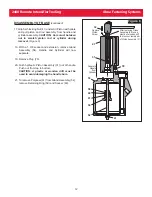

ASSEMBLY OF BASE

(Figures 10 & 14)

NOTE: See F

ILL

AND

B

LEED

P

ROCEDURE

FOR

D

ISASSEMBLED

T

OOLS

before proceeding.

1. Insert Plug (78).

2. Holding handle inverted in a vice, Place Cylinder

(53) on Handle (21) with Dowel (79) and Plug (78)

with O-Rings (74) in place

positioned in matching

holes.

(Figure 10a)

3. Assemble Gland Assembly (54) with Vibratite

505125. Screw complete Gland Assembly into

Handle. Torque to 100-120 ft. lbs. using 1-3/8 socket

wrench.

(Figure 10b)

4. Push Air Piston/Rod assembly with Quad Ring (50)

in place into Air Cylinder (51) until it bottoms at top

of Cylinder (53).

(Figure 10b)

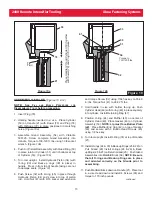

5. Turn tool upright. Install Hydraulic Piston (34)

(with

O-ring (33) and Back-up rings (38) in place)

in

handle. Press in from top of handle taking care not

to damage seals.

(Figure 14)

6. Push Screw (32) with O-ring (35) in place through

Hydraulic Piston (34) and screw into top of piston

rod. Hold Nut (41) with 9/16 socket and extension

and torque Screw (32) using 7/64 hex key to 55-60

in. lbs. Torque Nut (41) to 28-32 ft. lbs.

7. Hold handle in vise with bottom facing up. Push

Cylinder Head (49) with O-ring (48) in place squarely

into cylinder. Install Retaining Ring (47).

8. Position O-ring (44) and Muffler (43) on center of

Cylinder Head (49). Place Gasket (46) on Cylinder

Assembly (53).

NOTE: Lip must face Bottom Plate

(42).

Place Muffler End Cap (42) on top of Gasket

(46) and secure with 3 Button Head Screws (45)

using 1/8 hex key.

9. Turn tool upright. Install O-Ring (74) at top of Handle

(21).

10. Install O-rings (24 & 30) & Back-up Rings (25 & 29) on

Pull Gland (28) Install O-rings (24 & 26) & Back-

upRings (25 & 27) on Return Gland (23). Push Gland

Assemblies into Manifold Block (68).

NOTE: Be sure

that all O-rings and Back-up Rings are in place

and oriented correctly on the Glands prior to

assembling.

11. Push Manifold Block down on Handle (21). Place tool

in a vise Head down and install 4 Screws (69) and

torque to 170 inch pounds.

continued

78

74

(2)

21

53

79

Press Handle (21) and Cylinder (53) together with Dowel (79) and Plug (78) in place.

Figure 10a

Figure 10b

41

51

50

52

53

54

Torque to

100-120 ft.lbs.

Figure 10