14

2480 Remote Intensifier Tooling Alcoa Fastening Systems

Left half of

Handle (19)

Right half of

Handle (19)

Locknut

(100)

Qty. 4

Hydraulic Hoses

(63)

Qty. 2

Air Trigger

and Hose

Assembly (1)

Socket Head

Cap Screw (99)

Qty. 4

Head

Assembly

Built-in

Strain

Relief

Figure 9

ASSEMBLY OF HEAD

(continued)

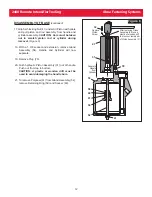

7. Assemble Hydraulic Hoses to Cylinder head

assembly. Use SLIC-TITE TEFLON thread

compound, or equivalent, on pipe threads.

8. Assemble Air Trigger Assembly as follows

: (Figure 3)

NOTE: For ease of assembly, heat end of hose

before pushing onto fittings. When using a new

quick disconnect, remove and discard plastic

ferrule from nut before attaching air hose to

quick disconnect.

a.) Push O-Ring 500777 over threads of Trigger

Body.

b.) Push Trigger Stem through Trigger Body, then

Stretch O-Ring 500772 over Trigger Stem and

into first groove.

c.) Screw Trigger Body with Stem in place into

Trigger Housing.

d.) Screw Hose Fitting into Trigger Housing. Push Air

Hose onto Hose Fitting.

e.) Slide Quick Disconnect nut over Air Hose. Push

Hose onto Quick Disconnect and tighten nut.

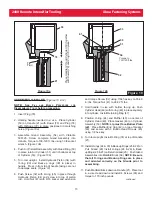

9. Assemble Handle as follows

: (Figure 9)

a.)

Position Air Trigger Assembly into left handle half.

Press air hose into handles built-in strain relief.

b.) Position assembled Cylinder and hoses in left

handle half. Align right handle half with left

(locators help align halves).

c.) Insert Locknuts and Screws into Handle. Tighten

Screws.