3

Gen IV Controller with Smart Arm Setup Instruction Manual

4. Hardware Connection

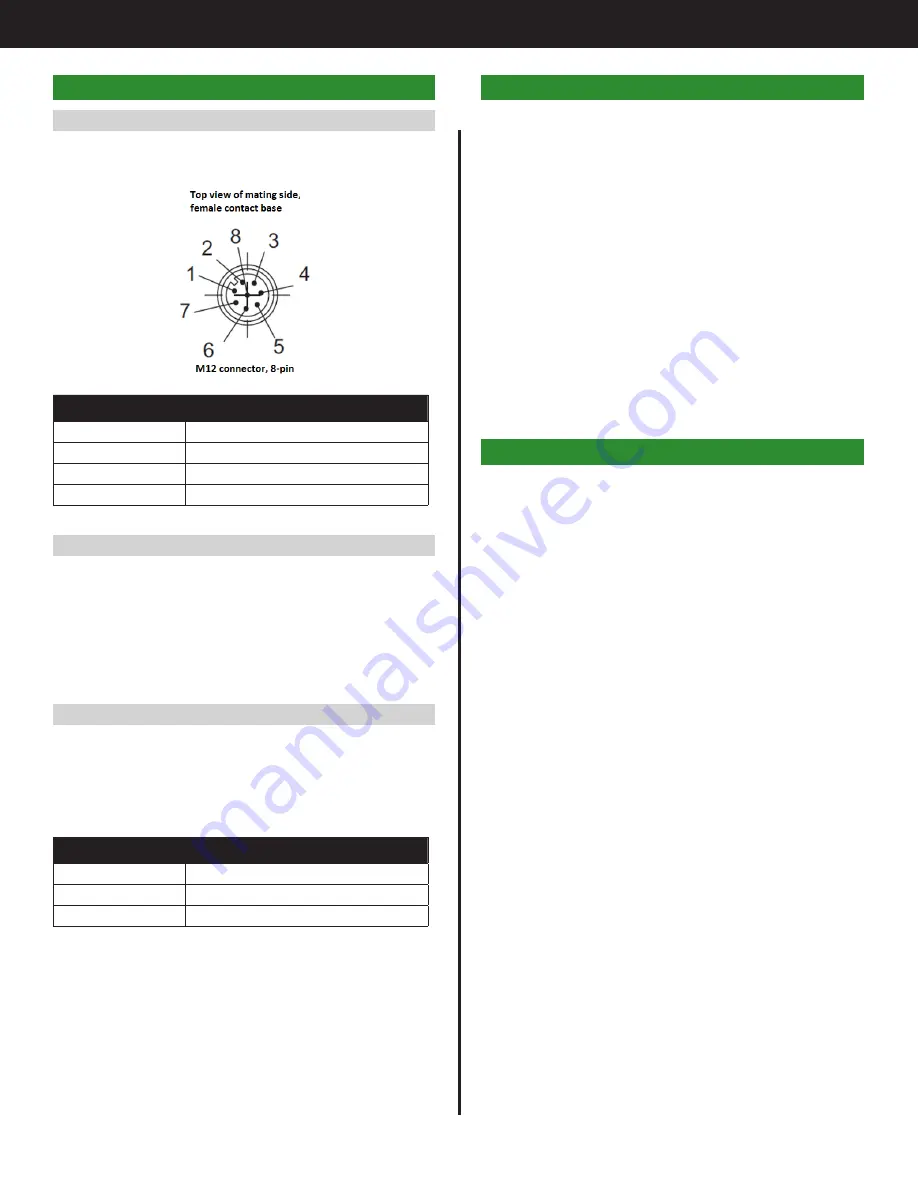

4.1 Connecting the Encoders

The encoders from the arm connect to the controller

via M12 connectors. The pinout is shown below.

Encoder Circuit M12-8 Bulkhead Connector Pin

0V

1

+12Vdc

2

A

3

B

5

4.2 Encoder Compatibility

The system is compatible with incremental encoders

with the following specifications:

•

Voltage: 12V

•

Signal output: Quadrature with A B outputs

•

Pulse rate: System verified with 2048 pulses per

revolution and lower

4.3 Connecting the Remote Home

An external remote home button can be added to

the accessory if needed. This will perform the same

function as the ‘Home’ button on the accessory

box. The homing function will be triggered when pin

4 on the M8 connection is pulled high to +12V.

External Circuit

M8-3 Bulkhead Connector Pin

0V

3

+12Vdc

1

Signal

4

5. Care Setup Steps Overview

This document covers the details of interfacing an

arm outfitted with encoders to a Gen IV Controller.

The general steps of the setup are:

1. Make all hardware connections

2. Power on the Smart Arm Accessory and Gen IV

Controller

3. Configure the accessory IP settings from the

controller

4. Add the Smart Arm accessory in the Gen IV

controller settings

5. Configure the accessory settings and add arm

locations

6. Add runscreen image (if required). Image must

be 470 x 550 pixels for best fit to controller screen

7. Configure line side control (if required)

6. Functionality Overview

The Smart Arm Accessory can interface with an

arm fitted with up to four encoders and/or proximity

sensors. A runscreen can be configured to show

fastener locations on a user uploaded image.

The controller is able to read the arm position

from the accessory box and perform an array of

different functions based on arm position. Setup

can be as simple as just selecting a PSet when the

arm is positioned over a fastener. It can also be

as complicated as combining line side control to

determine which fastener to insert with a Job and

Arm ensuring that the correct fastener is inserted in

the correct sequence while preventing fasteners

from being re-inserted.

Triggering the ‘Job Reset’ IO will clear the OK/NOK

status of any fasteners.

Содержание AcraDyne

Страница 15: ......