Содержание AL 65

Страница 8: ...Safety regulations...

Страница 29: ...Signs...

Страница 38: ...Technical data...

Страница 60: ...Description...

Страница 72: ...Operation...

Страница 83: ...Attachments...

Страница 91: ...Rescue towing lashing lifting by crane...

Страница 100: ...Maintenance...

Страница 120: ...Malfunctions causes and remedies...

Страница 123: ...Protection against theft...

Страница 126: ...Appendices...

Страница 127: ......

Страница 128: ......

Страница 131: ......

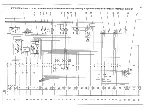

Страница 133: ...K65C K75C K95C K65C K75C K95C A 11 3 Muster Pr fhinweise f r Schaufellader A 11 3 Muster Pr fhinweise f r Schaufellader...

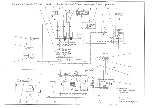

Страница 134: ...K65C K75C K95C K65C K75C K95C B B...

Страница 135: ...K65C K75C K95C K65C K75C K95C C C...

Страница 136: ...K65C K75C K95C K65C K75C K95C D D...

Страница 137: ...K65C K75C K95C K65C K75C K95C E E...

Страница 138: ...K65C K75C K95C K65C K75C K95C F F...