12 Installation Note E4411-90045

Removing the Lens/Keypad Assembly

1. The lens/keypad assembly is secured in place, with adhesive instead of hardware. To remove it from

the front frame, apply pressure along the edges of the lens from the front side until it pops out.

Replacing the Lens/Keypad Assembly

1. Remove the paper covering the adhesive on the lens/keypad assembly.

2. Carefully fit the new lens/keypad assembly into place in the front frame. Press along the edges of

the lens from the inside to adhere it to the front frame.

3. Make sure the inside of the lens is clean from contaminants such as lint and fingerprints before

proceeding.

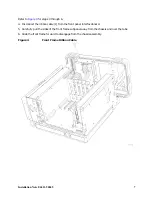

Replacing the Keypad/Flex Circuit

1. Place the main keypad (4) so it lays flat in the front frame (5). Be careful to avoid touching the

keypad contacts with your fingers.

Refer to

2. Lay in the flex circuit (3) so it aligns with the pegs on the front frame and lays flat. A small amount

of circuit ripple will be unavoidable.

3. Place the subpanel (2), with the display and the front panel interface board attached, on top of the

flex circuit, taking care to not pinch the flex circuit ribbon cable underneath.

4. Ensure that the water seal gasket on the volume control shaft is correctly positioned.

5. Ensure that the flex circuit is aligned with the pegs and not visible through the screw holes in the

subpanel. Replace the six screws that secure the subpanel to the front frame. Replace the four

screws that secure the display to the front frame. Torque to 101 N/cm (9 inch pounds).

6. Press the volume and RPG knobs onto their control shafts.

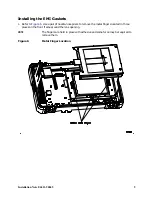

Reinstalling the Display

NOTE

If the LCD display requires cleaning, Isopropyl Alcohol on a soft wipe may be used

to gently wipe the glass lens of the display.

1. Place the display (4) into the front frame assembly. Make sure that the cables are not pinched

between the display and the front frame.

Refer to

2. Replace the four screws (3) that secure the display bracket to the front frame. Torque to 101 N/cm

(9-inch pounds).

CAUTION

The W3 display ribbon cable connector (2) is delicate. Use a small screwdriver or

similar tool to push the lock tabs into the back of the connector.

3. Connect the display ribbon cable (2) to the front panel interface board. Make sure that the display

ribbon cable is fully inserted into the connector body and aligned straight in the connector before

pressing the locking bar into place.

TIP

An easy way to insert this delicate cable into the connector is to place your finger

on the cable, in the center of the LCD display, and gently slide the cable away from

the connector until they align.