2. Position the plinth alongside the AGA Dual Control leaving no gap between the two plinths

(See Fig. 11).

Check with a spirit level that the plinth level is correct, and also check height differential

between the hotcupboard plinth and Dual Control plinth is correct (11mm). If necessary, use

shims in each corner to level the plinth.

Fig. 11

DESN 516276

HOTCUPBOARD

PLINTH BASE

11mm HEIGHT

DIFFERENTIAL

3. Attach hotcupboard plinth to the AGA Dual Control plinth using M6 screws and washers

provided (See Fig. 12).

Attach locking screw and jacking screw into plinth. Make sure at this stage that the jacking

screw does not protrude beyond outer face of plinth. Ensure locking screw is located into

AGA DC3 plinth but not fully tightened. A gap of approximately 3mm should be present

between the plinths apart from at the very front where the hotcupboard spacer plate should

be touching the AGA DC3 plinth.

Fig. 12

DESN 516550

15

+1

- 0

Содержание DC3

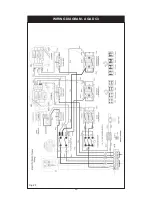

Страница 20: ...WIRING DIAGRAM AGA DC3 20 Fig 20 ...

Страница 23: ...23 ...