Set Up

DR500 Operation and Technical Manual

2-2

Aerotech, Inc.

Version 16

2.2.

DR500 Jumper Selections and Configurations

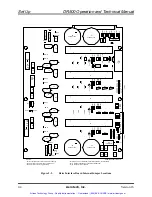

The DR500 is configured by the factory according to the specifications given by the user.

The user should not need to reconfigure the DR500 chassis. However, if there is a need

to add change the type of amplifier for an axis, it will be necessary to configure the slot

jumpers, shown in Figure 2-1 and Figure 2-2, according to the following sections. The

“BW” type slot jumpers on the Mother/Interface board are high current solid bus wire

jumpers and are soldered to the board. The “JP” type jumpers are two pin headers that

insert and pull out of a socket.

NOTE: There are two circuit boards within the DR500, be sure to reference the

correct jumper table for setting each board’s jumpers.

Figure 2-1.

Rear Panel Interface Board Jumper Locations

J12

11

J100

J10

FROM CONTROLLER P5

1

J11

I/O BUS

1

J3

AXIS 2

1

J4

AXIS 3

1

J2

AXIS 1

1

J5

AXIS 4

1

J13

MISC I/O

1

J16

ICMD

SIGNALS

1

J12

JOYSTICK

1

J14

BRAKE

1

J1

FROM CONTROLLER P1

DS5

I/O BUS POWER

DS1

ENCODER 1 POWER

DS2

ENCODER 2 POWER

DS3

ENCODER 3 POWER

DS4

ENCODER 4 POWER

1

R30

R29

R28

R27

R26

C4

C3

C1

C2

100UF

.001UF

10UF

10UF

BOTTOM SIDE

J10

J11

J3

J4

J2

J5

J13

J16

J14

J1

J100

R21

R20

R19

C6

P15

P14

1

1

EN1-N

PAD1

EN2-N

PAD2

EN3-N

PAD3

EN4-N

PAD4

JP28

JP29

1

JP14

J

P

4

J

P

3

J

P

2

J

P

1

2

8

7

1

2

8

7

JP5

6 7

JP8

12 10

JP13

JP9

TP12

TP1

22 32 42 2

TEST POINTS

Drawing 690D1529 Rev. D2

TOP SIDE

R6

R5

R4

R9

R8

R7

R18

R17

R16

C5 .1UF

.1UF

M1

M2

R

3

– C

11 –

.001

R

2

– C

10 –

.001

R1 – C9 –

.001

R

15 – C

17 –

.001

R

14 – C

16 –

.001

R

13 – C

15 –

.001

R

12 – C

14 –

.001

R

11 – C

13 –

.001

R

10 – C

12 –

.001

R

25 – O

P

E

N

C

8

– .001U

F

C

7

– .001U

F

R

24 – C

20 –

.001

R

23 – C

19 –

.001

R

22 – C

18 –

.001

7407

7407

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com